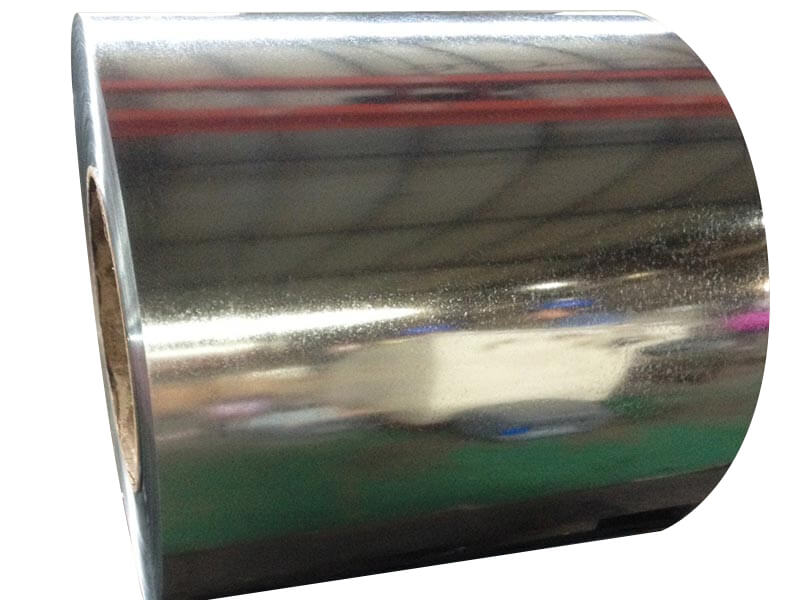

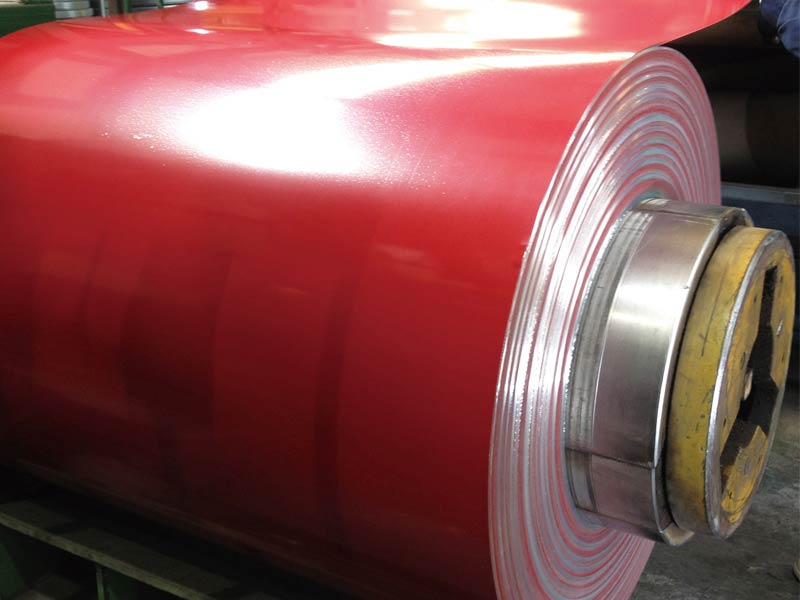

Full Hard Galvanized Steel Coil G550

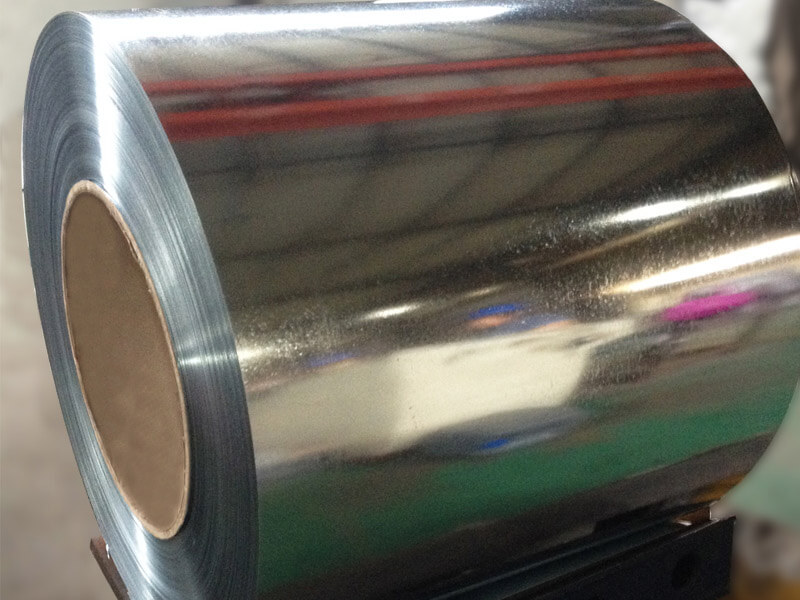

Full hard galvanized steel coil g550 refers to galvanized steel produced by cold-rolled unannealed strip steel and directly immersed in the plating bath without recrystallization

Cosasteel a steel coil manufacturer in China, PPGI coil and galvanized steel coil a product produced by our factory. Please contact us for any quotation.

Full hard galvanized steel coil g550 refers to galvanized steel produced by cold-rolled unannealed strip steel and directly immersed in the plating bath without recrystallization

Application Construction: Roofing, cladding, profiling, tiles, ceiling, Pre-engineered Buildings. General industry: Pipes, enclosures for electrical equipment, HVAC system. Appliances: Washing machines, tumble dryers, refrigerators. Aluzinc

Production Process The main production processes of the prepainted galvalume production line include pre-treatment process, coating process, and baking process. Uncoiling – sewing – degreasing

Organic-coated steel is created by applying an organic coating material on rolled metal strips through the continuous coil coating process. The application process involves cleaning

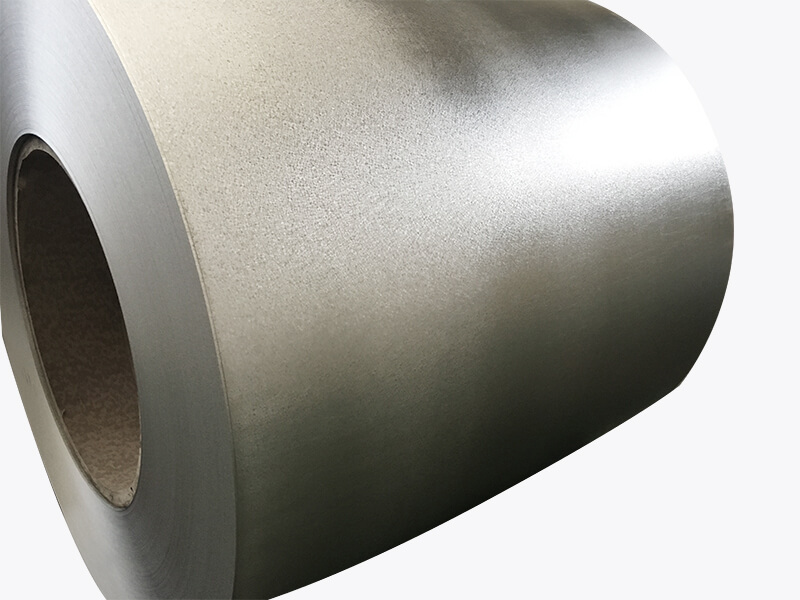

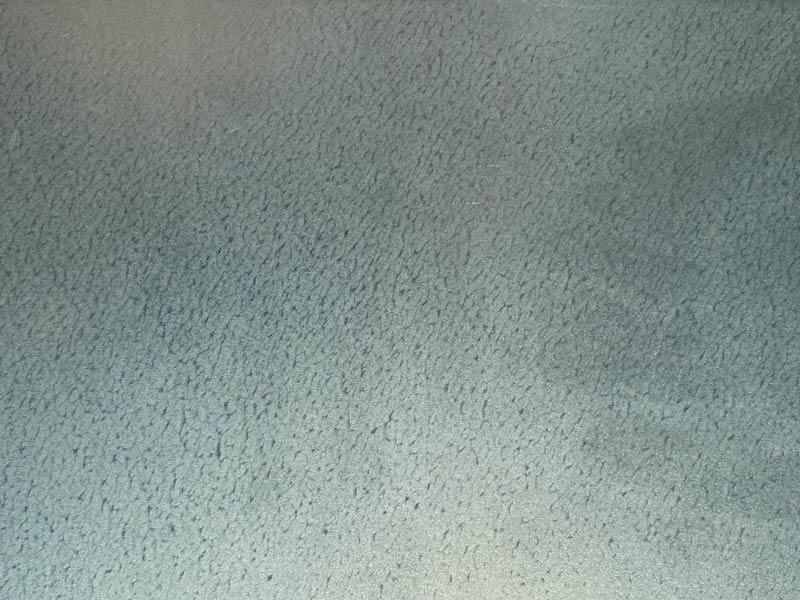

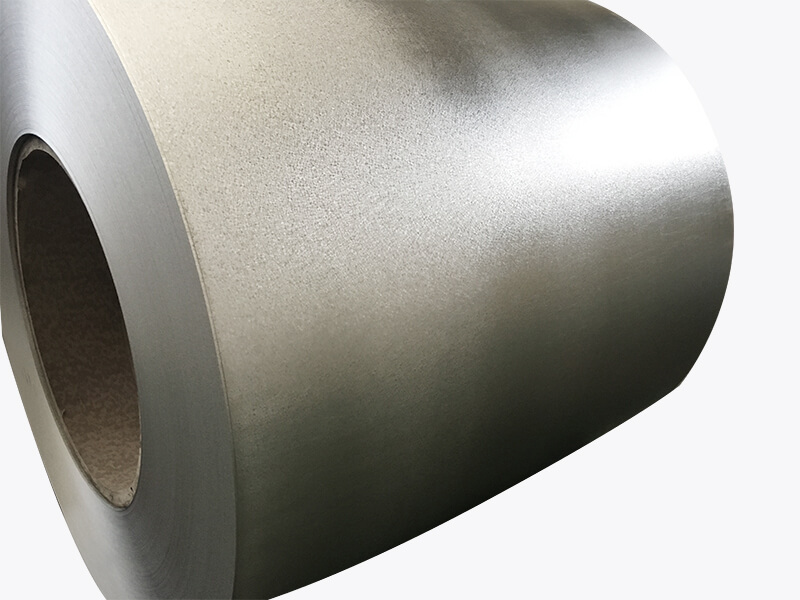

Zincalume steel coil with Activate Technology is a steel made by adding zinc, aluminum, or magnesium to the primary steel alloy, making it a robust

What is zinc aluminum-magnesium coated steel? The Zinc Aluminum-Magnesium coated steel is a new product in the global steel trading industry. It is a result

Mechanism of corrosion resistance Corrosion or rust may be avoided by creating a barrier on the surface of steel iron. This method is also known

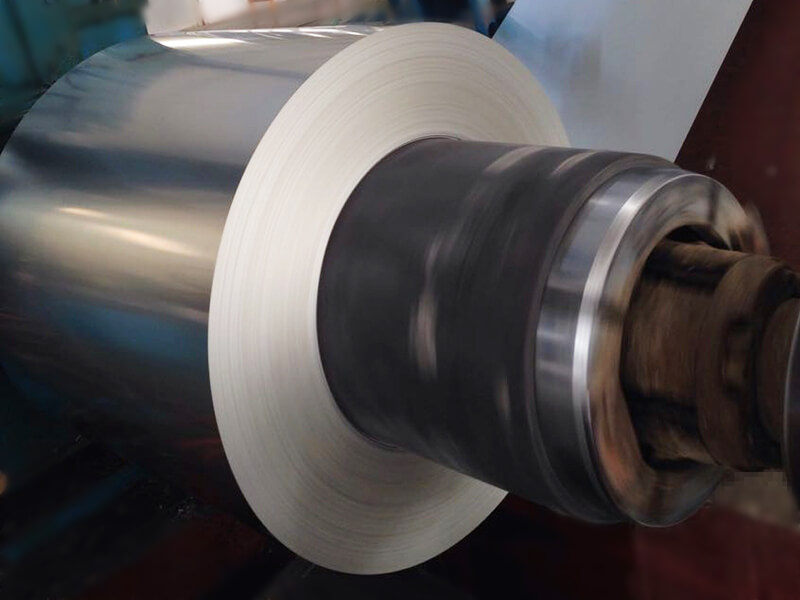

Production Process of Galvanized Steel Strip In the production process of galvanized steel strip, it has gone through very rigorous procedures and multiple production processes.

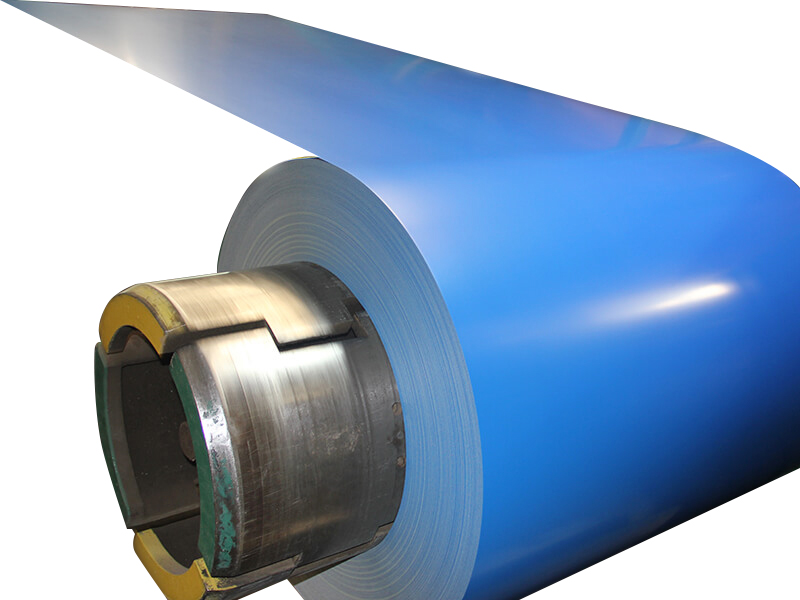

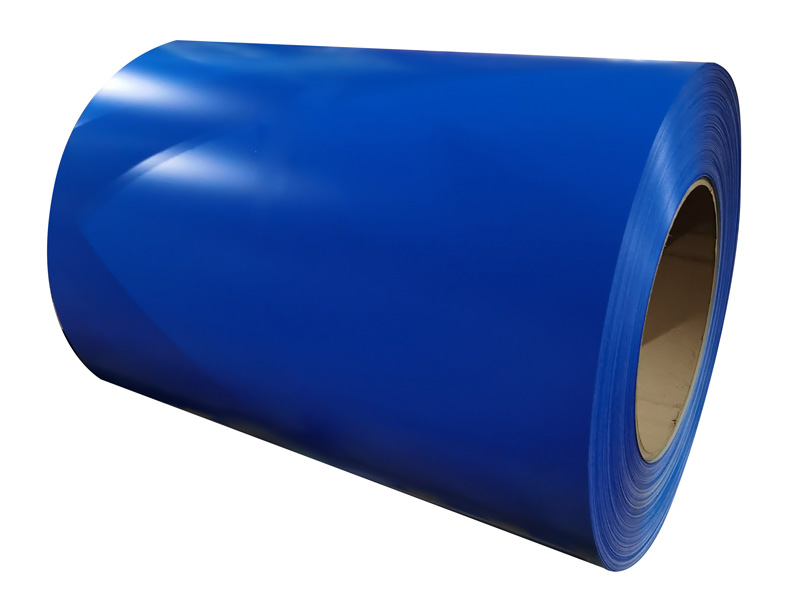

The pre-painted steel sheet is based on cold-rolled steel sheet and galvanized steel sheet, after surface pretreatment (degreasing, cleaning, chemical conversion treatment), and coating (roller

What is the use of Colour-coated steel? Construction Color-coated steel coils are mainly used in construction projects. After being processed into corrugated boards or sandwich

Surface Structure Spangled galvanized steel sheet is the spangle obtained by the condensation of the zinc coating under normal conditions after galvanizing. It is mainly

PPGL Coil uses DX51D+AZ, and q195 and galvalume steel sheet as the substrate, PE coating is our most commonly produced, it can be used for up to 10 years.

Uses of Prepainted Galvanized Steel Coils The main uses of pre-painted galvanized steel coils are home appliances and construction. Home appliance uses are mainly side

Material: CGCC, DX51D,Q195,Q235

Grade: SGCC,DX51D+AZ

Alu-Zinc Coating: 20-120g/m2

Thickness :0.13-0.7 mm

Width: 600-1250 mm

Coil ID: 508/610mm

Advantages of hot–rolled steel coil : 1) Hot rolling can significantly reduce energy consumption and reduce costs. During hot rolling, the metal has high plasticity and

Cold-rolled steel coils have good properties, and cold-rolled strips and steel sheets with thinner thickness and higher precision can be obtained by cold-rolling. High flatness,

Still not finding what you’re looking for?

Contact our consultants for more available products.

Copyright COSASTEEL | All Rights Reserved