Production Process of Galvanized Steel Strip

In the production process of galvanized steel strip, it has gone through very rigorous procedures and multiple production processes. Now I will introduce the production process of galvanized steel strip.

The first step is to use the pickling process to clean and decontaminate the surface of the strip. Because the dirt and rust that usually exist on the surface of the strip may not be cleaned up, it may affect the galvanizing work on the surface. Generally, the whole coil of strip steel is uncoiled after pickling, and then cleaned to make the surface clean and tidy.

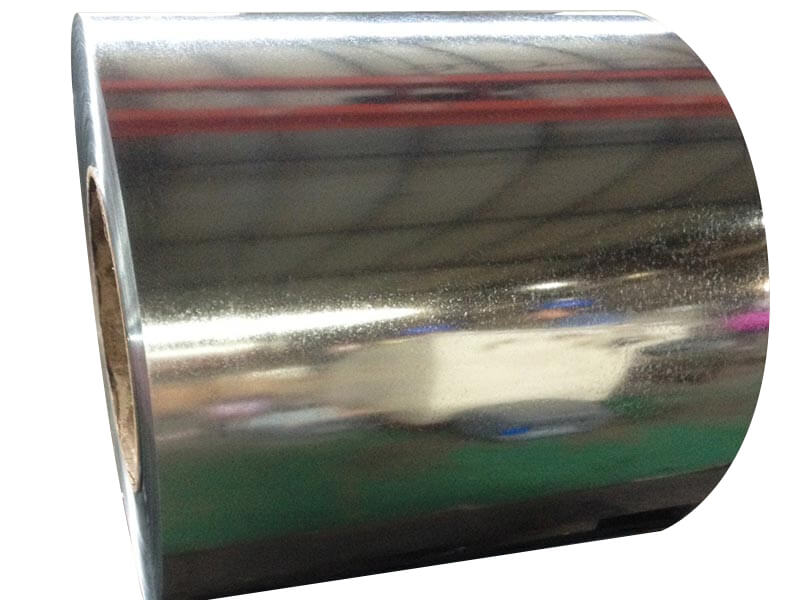

The second step is to mill the strip to the desired thickness and smooth the surface. After the rolling is completed, the next step is to galvanize it. The galvanizing work is actually very simple, just put it in a hot dip aqueduct, control the time and temperature, and you can get a smooth and uniform coating. Finally, put it into storage and you are done. The thickness of the galvanized layer is not fixed, and can be processed according to the different needs of customers.

Uses of Galvanized Steel Strip

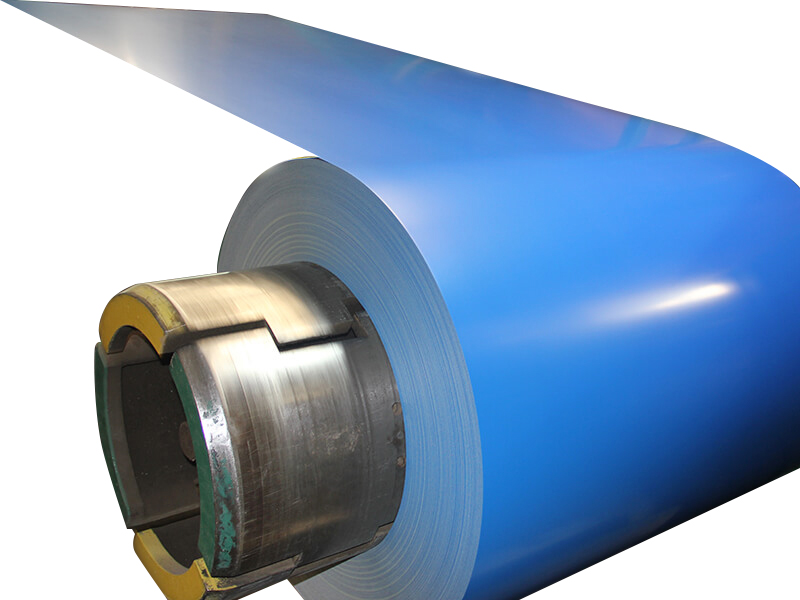

Galvanized steel strip as a new material. The principle is that the surface of the steel plate is plated with a layer of zinc, which uses the physical properties of zinc to play a role in anti-corrosion. As a new material, galvanized steel strip is the most widely used in construction and light industry, accounting for about two-fifths of the total application.

In addition, galvanized strip steel is widely used in daily life as a kind of anti-corrosion treated steel. Just because of different uses and different processing forms, we may not have noticed, such as the ventilation ducts of buildings, and some electrical surfaces, after beautification treatment, are usually used in places we cannot see, such as the back cover of refrigerators, etc. Wait.

Can galvanized steel strip be stored outdoors?

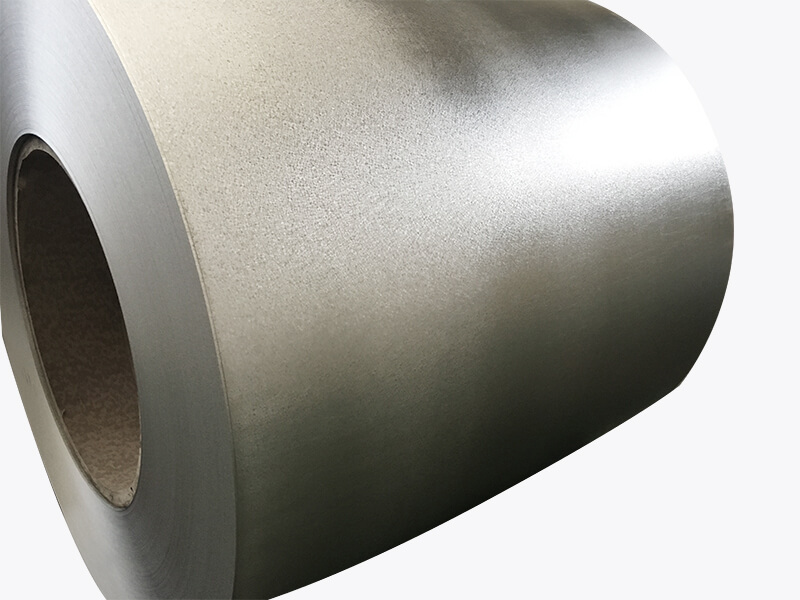

Galvanized steel strip is the technology of coating the steel strip with a layer of zinc through high temperature and chemical process. Compared with ordinary steel, galvanized strip steel has many advantages, such as strong corrosion resistance, long service life, more rust resistance and so on.

Galvanized steel strip cannot withstand the sun for a long time. It needs a dry environment, but remember not to be exposed to sunlight for a long time. Long-term exposure will cause the zinc on the surface of the galvanized strip to fall off, thereby reducing the life. If it is placed outdoors for a long time, it will not only be exposed to the sun, but also may be attacked by heavy rain and lightning. For galvanized strip steel, long-term wind and rain will corrode it, which is not good for it.

Quality Control of Galvanized Steel Strip

If galvanized steel strip is often used in an acidic environment, it needs to be processed with an acid solution when the product is processed. And some processing machinery parts are made of strip steel, which can prevent parts from being corroded. After the product is produced, in order to judge whether the quality of the product meets the standard, it is necessary to carry out a series of inspection work on the product:

- When testing, we must first check the appearance of the product, check whether the surface color of the product is bright, and then check the appearance size of the product to see if it meets the requirements.

- The thickness of the coating film on the surface of the product can be measured with accurate measuring equipment. When measuring, the distance between the measuring part and the equipment should be less than 3 mm, and the interval between the products should be about the same. point and calculate their average.

- After the production is completed, the product must be tested for the quantity of the product, and the experimental items and experimental methods used must comply with the regulations. Products made from galvanized strip are used in many processing industries and their role is irreplaceable. The quality of the galvanizing process directly affects the use of the product. Galvanized strip is processed from high-quality steel. Galvanizing density or galvanizing uniformity directly affects its performance.

How to Choose Galvanized Steel Strip

The first question is to see the thickness, width and length of the strip to be purchased, and then whether the galvanized strip to be purchased has flowers, and the requirements for the zinc layer. Finally, for its oiling situation, oiling is divided into light oiling and heavy oiling. There may also be environmental requirements for galvanized strip.

For galvanized strip, the quality of its quality mainly depends on the material and heat treatment of the strip, as well as the amount of zinc applied to hot-dip galvanizing. , 120 grams, at present, the weight of zinc in many factories is only about 40 grams, and the weight of zinc directly affects the anti-corrosion ability.

For the galvanized strip steel with poor quality, there are cracks on the surface, which are mostly caused by cracks and poor annealing, and the material is too hard.