What is zinc aluminum-magnesium coated steel?

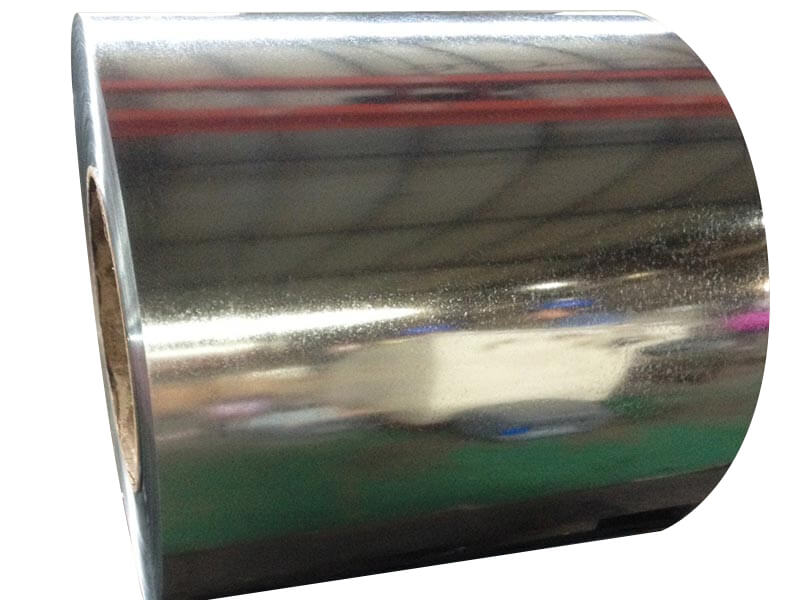

The Zinc Aluminum-Magnesium coated steel is a new product in the global steel trading industry. It is a result of various extensive steel manufacturing researches done to enable steelmakers to produce coated steel that is better than galvanized steel.

This type of coated steel is a highly improved version of a corrosion-resistant steel plate which is made mostly of zinc (Zn), combined with a set amount of aluminum (Al) and magnesium (Mg). ZAM coated steels are widely used in different types of construction and can be formed in any kind of steel parts or shape.

Comparison of corrosion resistance with galvanized steel

Galvanizing is a production method in which steel or iron is applied with a zinc coating to provide protection against corrosion or rusting. This technique, most especially the hot-dip galvanizing method, is widely used in manufacturing steel products.

NIPPON STEEL Corporation, however, with its goal to become the best steelmaker worldwide, has paved the way in manufacturing a better quality steel sheet product with its ZAM® coated steel. This product is better in all aspects than galvanized steel because of its higher corrosion resistance, cost and time efficiency, and more.

ZAM® coated steel sheets outperform galvanized and hot-dip zinc with 5% Al coated steel sheets in terms of red rust resistance. To prove this, ZAM products underwent outdoor exposure tests with galvanized and hot-dip zinc 5% Al steels in a rural environment at Kiryu-City, Gunma, and a coastal environment at Nakagusukuson+, Okinawa.

The exposure test lasted for a span of 8 years. In the rural setting, results revealed that the corrosion loss of ZAM coated steel is only at approximately 16-24 g/m2, while zinc with 5% Al coated steel is at ~38-51 g/m2, and the galvanized steel is at ~76-89 g/m2.

In the coastal environment, the corrosion loss result of ZAM® coated steels is ~33-43 g/m2, zinc with 5% Al coated steel is at ~66-82 g/m2, and the galvanized steel is at a high rate of ~105-115 g/m2.

In conclusion, ZAM coated steels are up to four times more corrosion-resistant than galvanized and hot-dip zinc 5% Al coated steels.

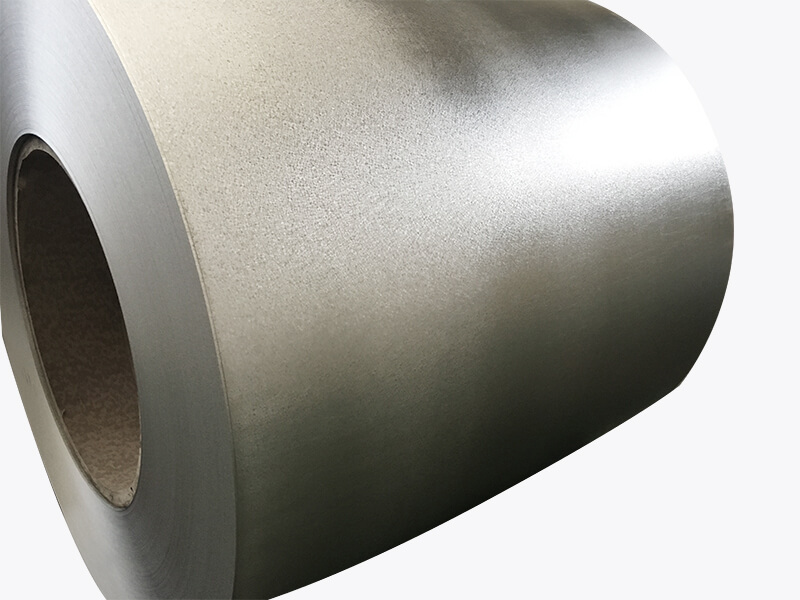

Superior properties of ZAM coated steel

ZAM Coated Steel is an incredible brand product that lasts a lot longer even in the harshest environment settings, has built-in rust prevention on the cut edges and excellent press formability, and reduces the manufacturing cost by requiring less maintenance.

Highly resistant to steel corrosion

The non-oxidizing chemical properties of magnesium added to the traditional hot-dip zinc coating steel sheet make it up to 20 times more resistant to corrosion. Also, up to eight times more resistant compared to hot-dip zinc steel sheets coated with 5% aluminum alloy.

Excellent Press Formability

The steel sheets of ZAM are built with a firmer and smoother coating surface compared to those made from hot-dip zinc coating. This is the reason why ZAM® coated steel sheets do not crack during forming conditions. After the shaping process, the flange area is also reduced.

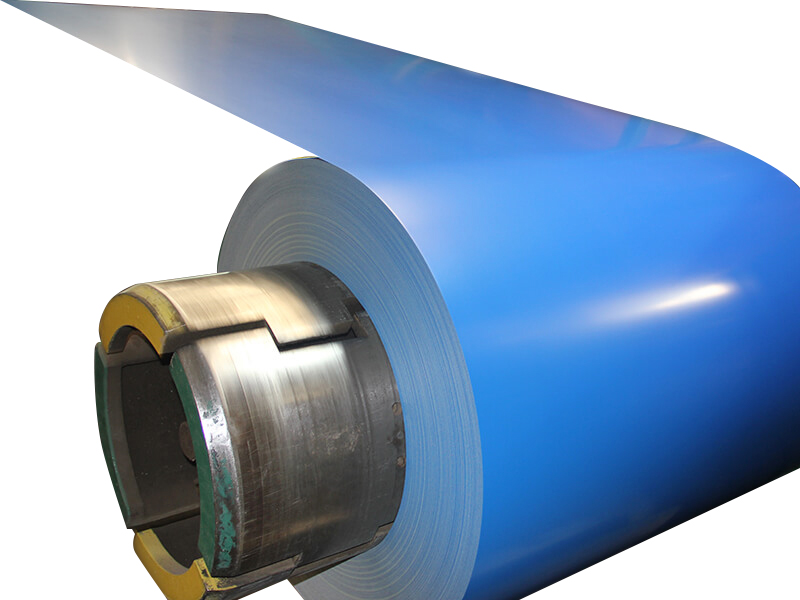

Reduces manufacturing costs significantly

ZAM coated steel helps save manufacturing costs notably in a variety of ways. Again, because of its enhanced corrosion resistance, it allows life cycle cost reduction. It also allows for upfront cost savings through process omission.

Other exceptional properties:

- Product Longevity ー ZAM coated steel sheets are more sustainable than other steel products

- Light coating weight ー Plate thickness is only at 3.2 millimeters, but firmer

- Environment-friendly ー All product treatments adhere to environmental requirements, including RoHS directives to avoid the dangers of electrical waste disposal, and ELV systems to ensure that the system is controlled at a low voltage

- Saves coating and transportation costs ー ZAM contributes to cost reduction and shortens delivery time by eliminating the post-hot-dip galvanizing process

ZAM coated steels may be produced in a wide range of forms for different types of construction projects. It may be formed into a corrugated sheet, punching metal, non-slip metal, lightweight structural steel, pre-notched shaped steel, square pipes, and round pipes.

ZAM can be used for road construction such as building railings and other civil engineering projects. It may also be utilized for farming projects such as establishing a greenhouse, compost house, or fish preserve. Lastly, ZAM® coated steels are also utilized in railroad and housing structures, the building of electric power equipment and automobile parts, and other applications.