Surface Finish of Galvalume Steel

|  |  |  |

| Normal(non-skinpassed)spangle | Skinpassed spangle | Regular spangle | Minimized spangle |

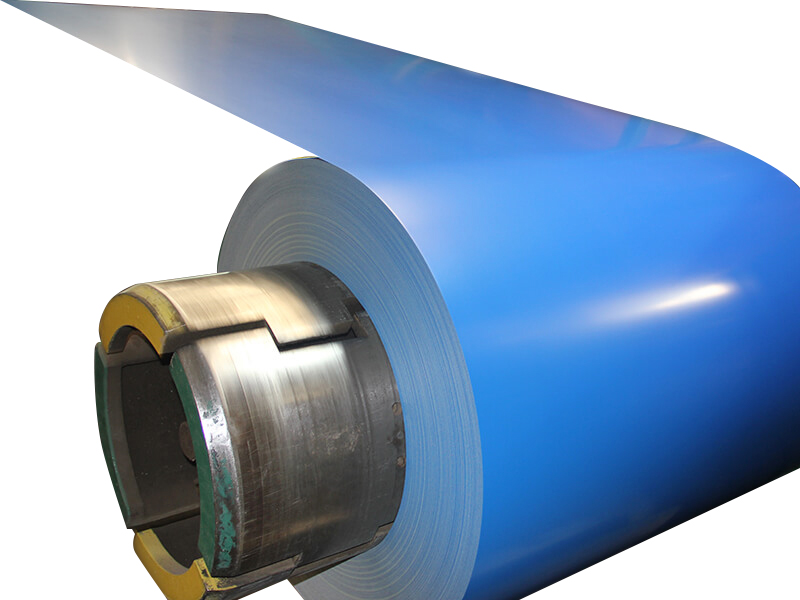

Surface Treatment of Galvalume Steel Sheet

| Item | Classification | Symbol |

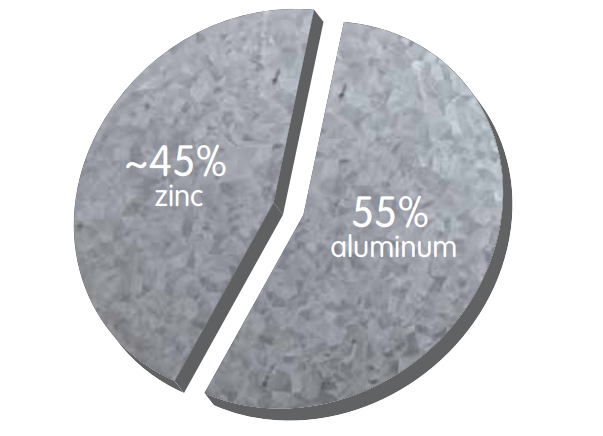

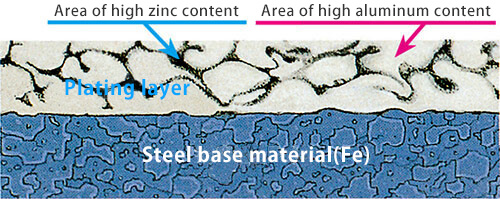

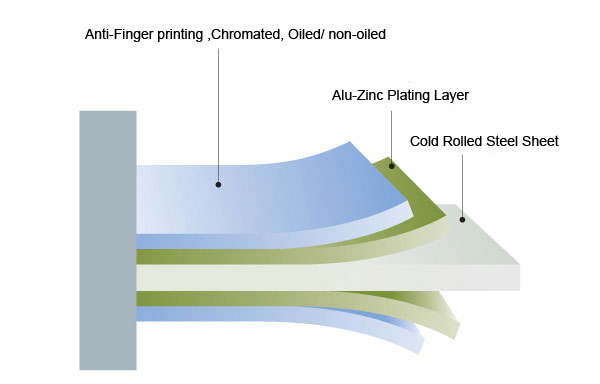

| Coating type | Al-Zn alloy | AZ |

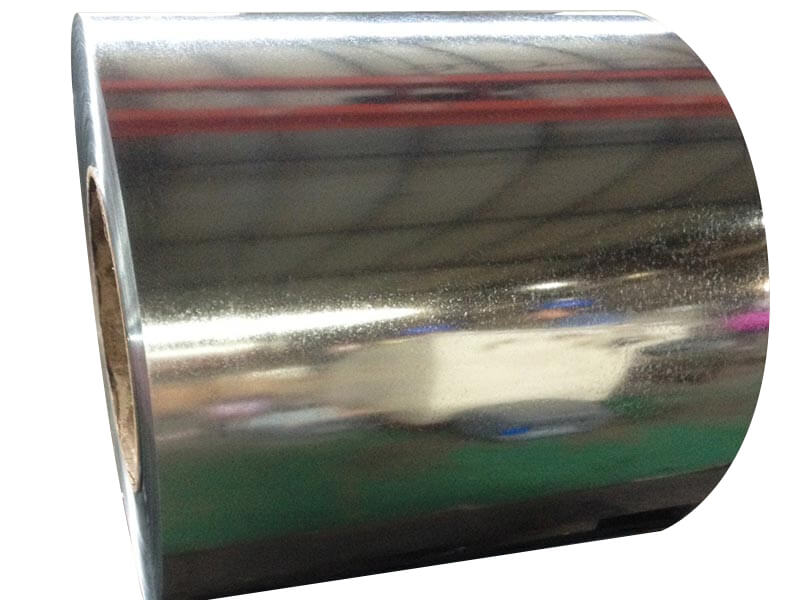

| Surface finish | Regular spangle | R |

| Minimized spangle | M | |

| Skin passed | S | |

| Surface treatment | Chromate passivated | c |

| Non-chromate passivated | C5 | |

| Chromate passivated + oiling | CO | |

| Non-chromate passivated+oiling | CO5 | |

| Anti-fingerprint | N | |

| Non-chromate anti-fingerprint | N5 | |

| Non-chromate high weather resistance anti-fingerprint | NW | |

| Oiling | 0 | |

| No treatment | U |

Applications for Galvalume Steel Sheet

Construction: civil and industrial building roofs, facades, substrates for painted rolls, garage doors.

Industrial instruments: electric control cabinets, industrial freezers, vending machines.

Usually, building roofs are the most widely used.

5/5 - (27 votes)