Quality control

Quality Inspection Process

In order to ensure zero-defect production of products, we have established a complete product quality management process and realized process control of color-coated products.

Warehouse acceptance for hot-rolled coils

Confirm whether the order requirements match the raw material grades

Galvanized inspection

Zinc layer weight, zinc layer thickness, adhesion, surface treatment, spangle style(zero or big spangles) etc.

Substrate Inspection

Appearance, strength, material, grade, etc.

Prepainted inspection

Coating thickness, coating surface quality, coating thickness, pencil hardness, impact, etc.

COSASTEEL considers the basic parameters listed below in designing and testing the quality of its products.

Steel Sheet Thickness

COSASTEEL ensures that all of its products adhere strictly to the ordered nominal thickness, and does not exploit the extreme negative tolerance allowed by international standards, since a lower thickness will make a sheet structurally weaker.

Zinc Coating Mass

The service life of zinc-coated steel has a direct linear co-relation to the zinc coating mass, and is the primary parameter in determining the corrosion resistance of galvanized and pre-painted sheet products in outdoor environments. COSASTEEL is committed to meeting a minimum of 90 gsm zinc coating mass on pre-painted steel sheets for use in dry climate conditions.

Paint Thickness

COSASTEEL uses only the highest quality paints from reliable international sources and ensures that paint thickness meets international standards.

Standardized Detection Method

COSASTEEL has two laboratories: one for testing galvanized steel products and another for pre-painted galvanized steel products. Both laboratories have state-of-the-art facilities sourced from renowned agencies from USA and UK to carry out the testing and evaluation of galvanized and pre-painted steel products.

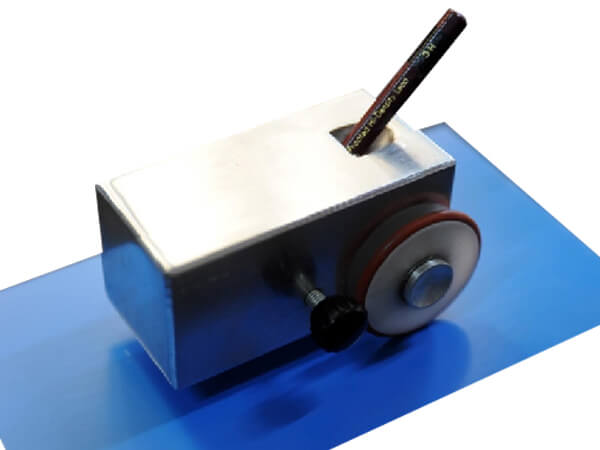

Bending Test

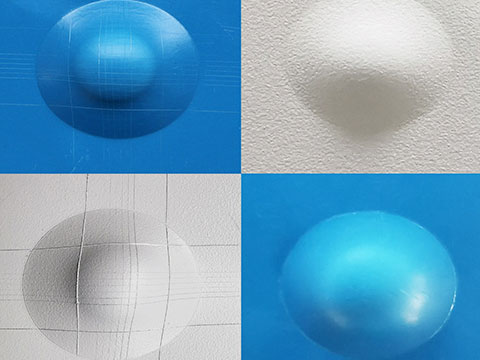

Gloss Test

Stretching Test

Color Difference Test

Salt Spray Test

Hardness Testing

Coating thickness test

Product Aging Test

Reverse impact and checkered