Uses of Prepainted Galvanized Steel Coils

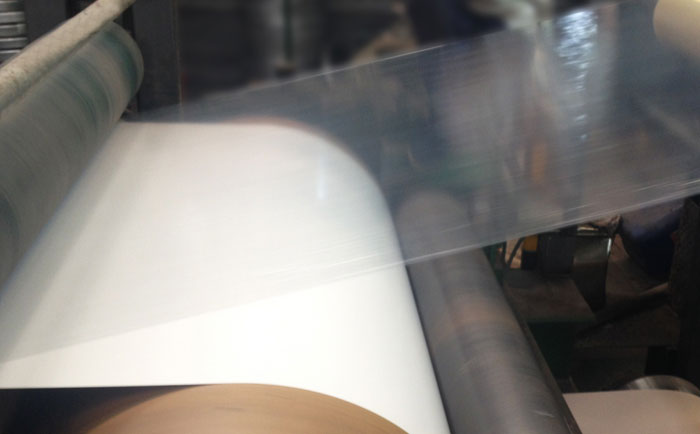

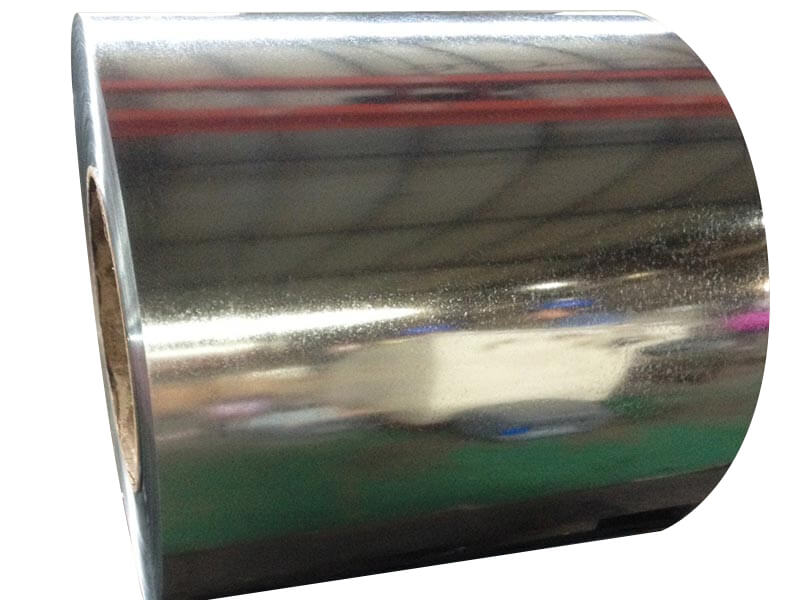

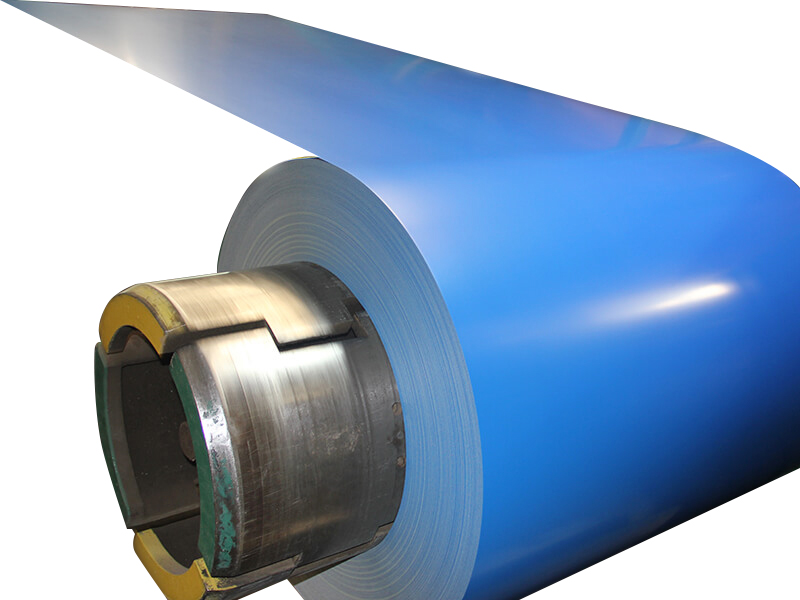

The main uses of pre-painted galvanized steel coils are home appliances and construction.

Home appliance uses are mainly side door panels for refrigerators, and shells for air conditioners, freezers, and washing machines. The construction field is more widely used than home appliances.

PPGI coil for construction is used for roofing, guttering, sandwich panels, industrial building facades, cold storage panels, and rolling doors.

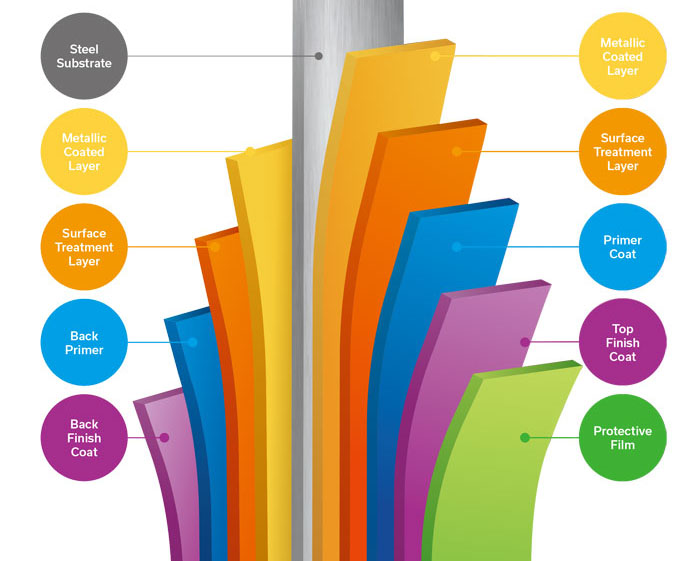

Z275, Z150, and Z100 can be used for the pre-painted steel coils. For less demanding environments use Z40 zinc and polyester coatings.

5/5 - (31 votes)