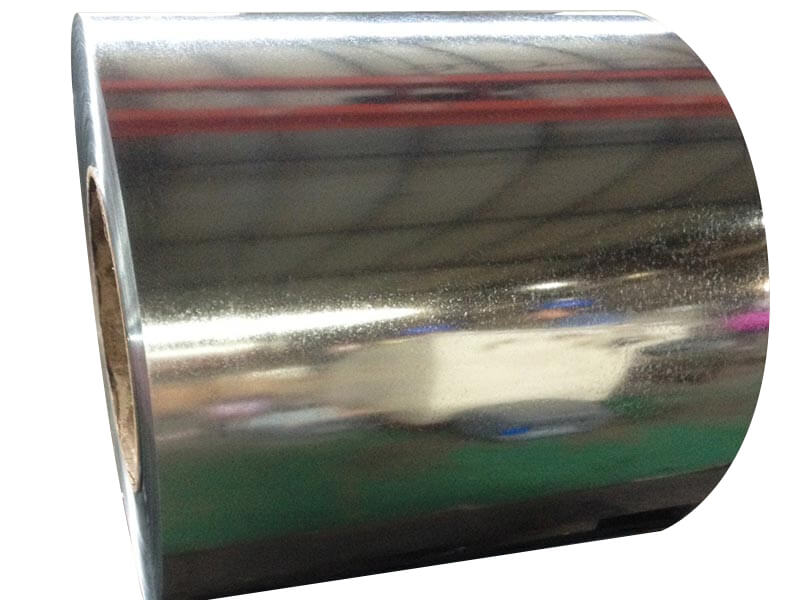

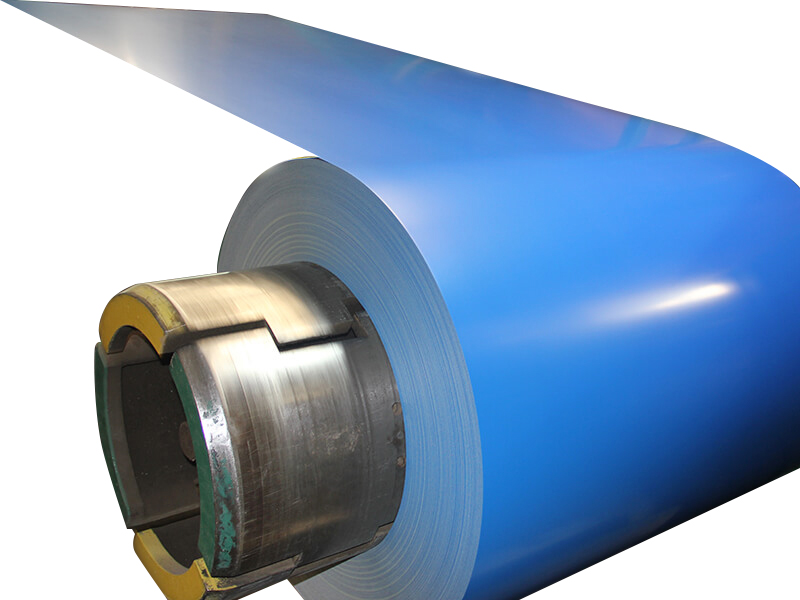

Cold-rolled steel coils have good properties, and cold-rolled strips and steel sheets with thinner thickness and higher precision can be obtained by cold-rolling. High flatness, high surface finish, clean and bright surface of cold-rolled sheet. It is easy to be coated and processed and has the characteristics of high stamping performance and low yield point, so cold-rolled steel coil has a wide range of uses, mainly used in automobiles and building materials. At the same time, it is also the substrate for the production of galvanized steel sheets in coil and galvalume steel coil.

Cold Rolled Steel Coil Grades

Cold-rolled steel coils are also divided into many grades by materials. The following are the grades of several commonly used countries.

Japanese Grade

JIS standard: JIS G 3141 – 2005, There are 5 main types:

SPCC stands for cold-rolled steel coil for general use

SPCC——S-steel (Steel), P-plate (Plate), C-cold rolling (cold), the fourth C-common grade (common).

SPCD stands for stamping

SPCE stands for deep drawing

SPCF stands for extra deep drawing

SPCG stands for super deep drawing

In terms of chemical composition, the difference between them is mainly the content of trace elements such as C, Mn, P, and S.

European Grade

Basically the same: EN 10130/EN 10139 can be applied without much difference.

Divided into 5 types:

DC01 stands for cold-rolled steel coil for general use

DC03 stands for stamping

DC04 stands for deep drawing

DC05 stands for extra deep drawing

DC06 stands for super deep drawing

German grade

ST12——ST-Steel, 12-common grade cold rolled steel coil

Advantages of cold-rolled steel coil:

1. The product size of cold-rolled coils is accurate, the thickness is uniform, and the thickness difference of the coils generally does not exceed 0.01-0.03mm or less, which can fully meet the requirements of high-precision tolerances.

2. Available to extremely thin strips that cannot be produced by hot rolling (the thinnest can reach 0.001mm or less.

3. The surface quality of cold-rolled products is superior, and there are no defects such as pits and pressed iron oxide scales that often occur in hot-rolled coils. And according to the requirements of users, it can produce coils with different surface roughness (glossy surface or hemp rough surface, etc.) to facilitate the processing of the next process.

4. The mechanical properties and technological properties of cold-rolled steel coils are very good (such as higher strength, lower yield limit, good weight deep drawing performance, etc.).

5. High-speed rolling and full continuous rolling can be realized, with high productivity.

The difference between cold-rolled steel coil and hot-rolled steel:

1. Appearance and surface quality: Cold-rolled steel coil is better in surface quality (such as Surface roughness) than hot plate because it is obtained by cold rolling and some surface finishing is carried out at the same time. Therefore, if the product after the sequence of painting, such as coating quality, there are higher requirements, the general choice of the cold plate. The hot plate is divided into the pickling plate and the unpickling plate. The surface of the pickling plate becomes the normal metal color because of pickling, but the surface of the unsold-rolled plate is not as high as that of the cold-rolled plate, or the existence of ferrosoferric oxide layer, colloquially it is fire-roasted, and if the storage environment is not good, usually with a little embroidery.

2. Properties: In general, the Mechanical Properties of hot and cold-rolled steel coil are considered to be the same in engineering, although there is a certain amount of work hardening during cold rolling, (but not rule out the case of strict mechanical performance requirements, it needs to be treated differently), cold-rolled steel coil usually than hot plate yield strength slightly higher, surface hardness is also higher, how specific need to see cold plate annealing degree. However, the strength of the annealed plate is higher than that of the hot plate.

3. Forming performance: Because the performance of cold and hot-rolled steel coil is basically not too much, so the forming performance of the influence factor depends on the difference of its surface quality, because the surface quality is the cold-rolled steel coil to be better, so generally speaking the same material steel plate, the appearance of cold plate is better than that of the hot plate.

What is cold-rolled coil used for?

The application fields of cold-rolled coils are very wide, such as automobile manufacturing, electrical products, rolling stock, aviation, precision instruments, canned food, etc.