Introduction:

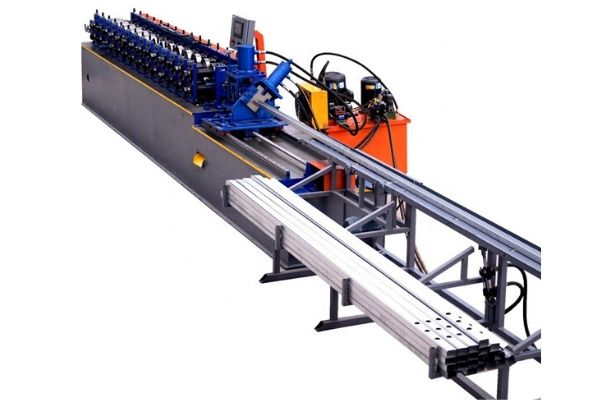

The products produced by the highway guardrail roll forming machine have the characteristics of lightweight, high strength, large bearing capacity, and good seismic resistance, and are widely used in the field of multi-rise steel structure buildings.

Highway guardrail produced by the highway guardrail roll forming machine is a continuous structure, which is composed of corrugated steel guardrail board, each piece of which is fixed on the pillar of guardrail board through splicing to form a whole. This structure composed of corrugated guardrail board is not only beautiful in appearance but also convenient in application.

When impacted, the wave-shaped guardrail will absorb the huge impact force through the deformation of itself, the pillars and beams, so as to achieve the purpose of changing the direction of the vehicle out of control to avoid the phenomenon of the vehicle rushing out of the road.

Advantages of the Highway Guardrail Roll Forming Machine:

- The highway Guardrail roll forming machine is controlled by PLC control system, and multiple protections are established during normal production.

- The bed is made of the welded steel plate and tempered to eliminate internal stress to avoid the deformation of the fuselage.

- The transmission structure is gearbox transmission. Each forming frame has a gearbox, which can guarantee the equipment running overtime, in high intensity, and having a long service life.

General principles of two-wave and three-wave highway guardrail roll forming machine:

Because the highway guardrail roll forming machine needs to achieve the purpose of simultaneous production of two-wave and three-wave guardrail, the highway guardrail roll forming machine specifically adds the following configuration:

- Specially added hydraulic drive system, so that it can automatically set the length and punching distance of the plate. The processing rate can reach about 10-12 meters/minute;

- The cutting part is equipped with a cutting head that produces three-wave guardrails;

- Two sets of punching moulds: one set of 80-ton hydraulic press and one set of the 200-ton hydraulic press;

- In addition to using Q235 for processing materials, high-strength materials like S400 or S540 can also be used.

General use method of highway guardrail roll forming machine:

- When producing three-wave highway guardrail boards, the punching device will be adjusted to three-wave punching mould. The length of the board and the distance between the punching holes are set by the control system to allow normal mass production.

- When producing two-wave highway guardrail boards, the punching device needs to be replaced with a two-wave punching mould. The outermost row of wheels above the pressing roller can be adjusted outwards appropriately. When feeding, the pressure plate can be placed on one side, so that when cutting, it can cut out the size of 2 waves. Then punched and shaped to produce two-wave highway guardrail boards. If the outer pressure roller does get in the way, you can remove it.

FAQ:

The difference between the use of two-wave highway guardrail and three-wave highway guardrail:

As we all know, the wave guardrail is a collision guardrail installed on a highway or a country road. Its function is mainly to prevent vehicles from rushing out of the driving range of the road and avoid causing extremely serious traffic accidents.

For two-wave guardrails: Rural roads are not as straight as highways. Moreover, it is impossible to predict whether a vehicle is driving ahead on a curved country road. Naturally, driving speed will reduce a lot for safety reasons. Therefore, when installing anti-collision guardrails, two-wave guardrails can be applied.

The height of the double-wave guardrail (310mm high) is 3/5 of that of the three-wave guardrail (506mm high). The thickness of the double-wave guardrail plate (thickness 2.5mm) is 0.5mm smaller than that of the three-wave guardrail plate (thickness 3.0mm). According to the comparison, customers can install two-wave guardrails to save costs and avoid unnecessary waste.

For three-wave guardrails: The highway is relatively straight and the driving speed is extremely fast. In the event of an accident, if you want to prevent the vehicle from rushing out of the road, you first need to adopt 506mm high, 3.0mm or 4.0mm thick guardrails to increase the rigidity and toughness of the guardrail itself. Therefore, the application of three-wave guardrails on highways is more appropriate than two-wave guardrails.

The Specification of Highway Guardrail Roll Forming Machine:

Product: Highway Guardrail Machine

Tile Type: Colored Steel

Voltage: 380v, 50Hz, 3phase

Weight: 5.5t

Shearing System: Automatic hydraulic control

Production Capacity: 10-12m/min

Dimension(L*W*H): 7200mm*1600mm*1800mm

Control System: Automatic computer control

The material of Cutting Plate: Cr 12

Mainframe: 300H steel

Roller materials: 45# steel hard chromium plating

Main power: 4kw

Material thickness: 0.3-0.8mm

Made board: 16mm

Feeding width: 1200mm

Application Industries: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Construction works

Price: $55,000.00 – $85,000.00