Laboratory

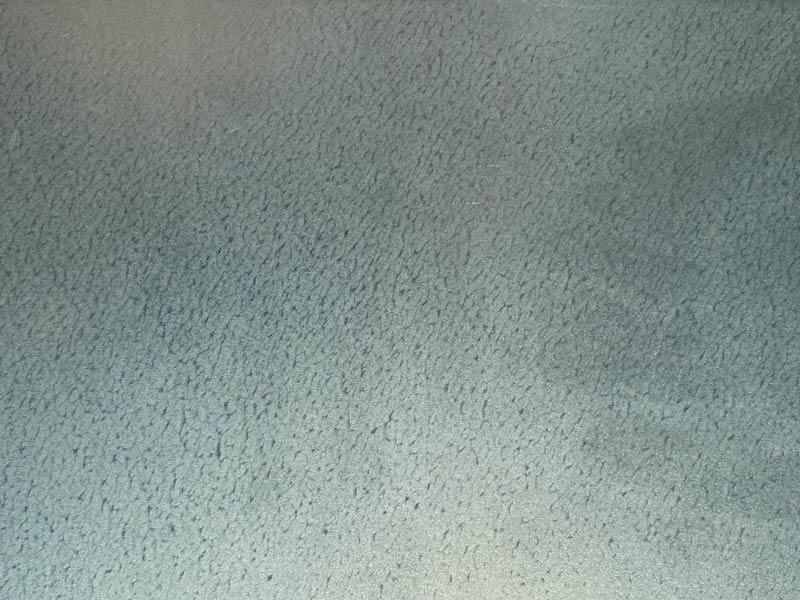

Fully equipped galvanized and pre-painted steel laboratories for testing and evaluation of products.

Free Sample

We do sample production according to your specifications, you may need to pay the courier fee

After-Sales

The quality of the pre-painted steel is found to be defective during use, and the evidence is retained for claim settlement.

Quality Assurance

Precise Dimensional Tolerances & Tight Control on Zinc Coating Mass. Paint thickness without cutting corners. For some suppliers, the actual product does not match the specification.

What We Offer

Focus on metal coil industry

Free Sample Testing

The composition of the steel coils sold by some suppliers does not match, and the specifications of the pre-painted steel cannot be judged by the naked eye. COSASTEEL provides free sample testing

Who we are

Reliable Steel Coil Supplier

COSASTEEL is a PPGI coil , galvanized coil, aluzinc coil manufacturer in China. We cooperate with PPG, Beckers, valspar, Nippon and other well-known paint brands to ensure the service life of pre-painted steel. We have the ability to produce Z275 galvanized and AZ150 galvalume. We have 7 steel coil production lines, which have improved the product production capacity.

Featured Articles

Read Knowledge of Steel Coil

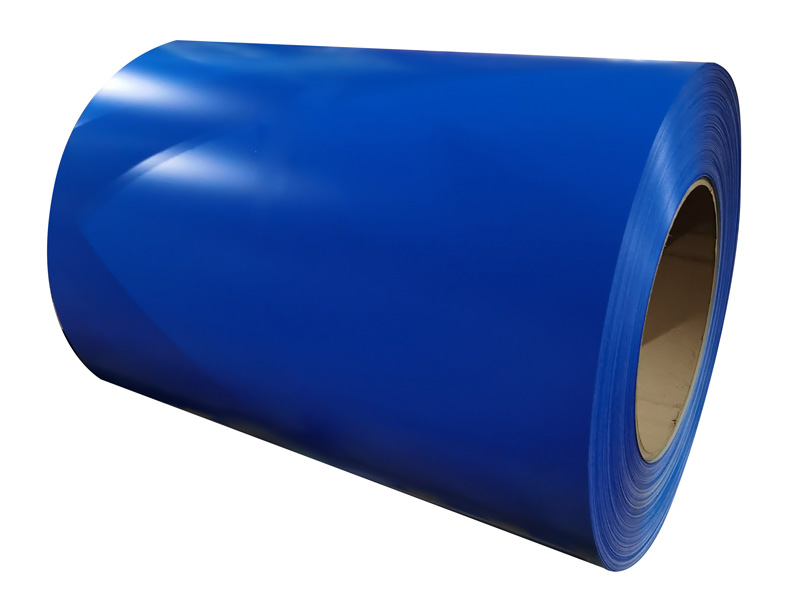

Prepainted Galvanized&Galvalume Steel Coil

Prepainted steel coil undergoes several stages to ensure its high performance for various applications. Find out why prepainted steel is more cost-effective and superior than

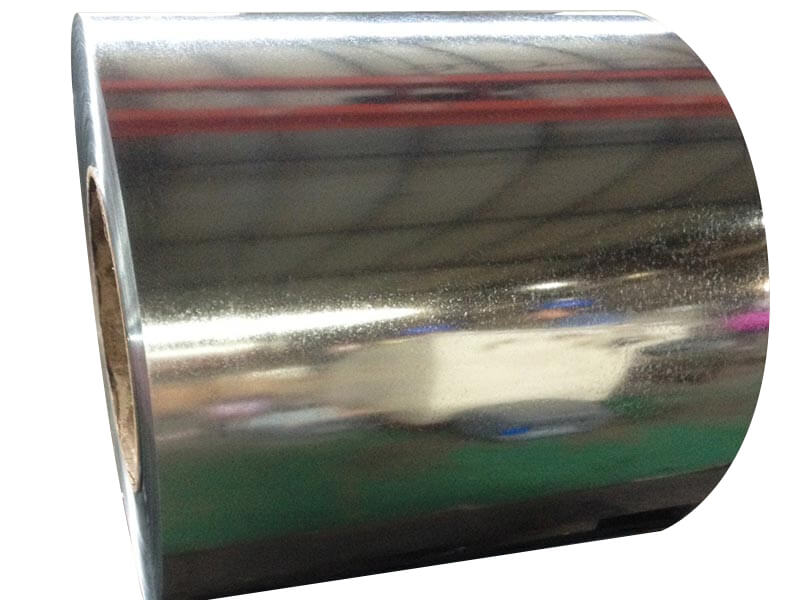

Galvanized Steel Coil

The addition of zinc in the hot-dip galvanizing process serves as a protective barrier against harsh environments and impurities. Learn more about galvanized steel coil

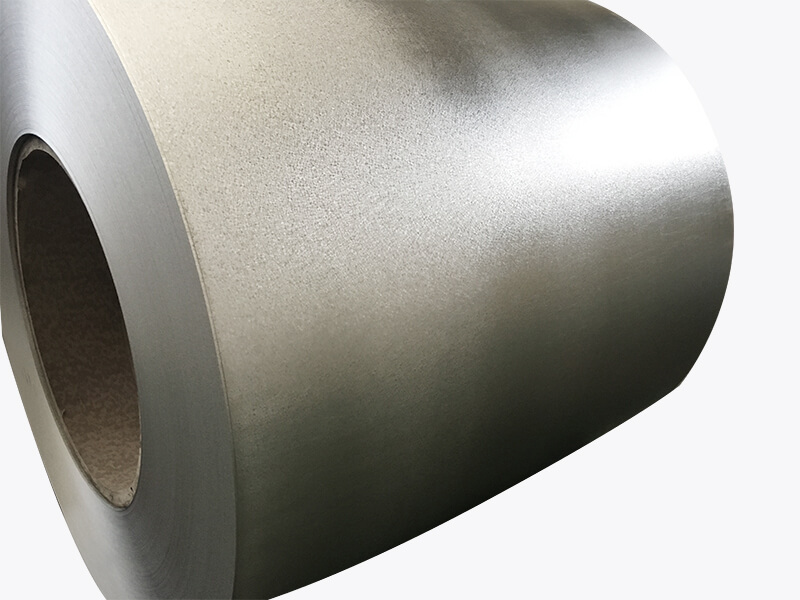

Galvalume Steel Coil

Galvalume steel coil is a type of steel with a coating of aluminum and zinc, protecting it from oxidation. Learn more about the basics of

PPGI Coil: Purchase Guide and Knowledge

PPGI coil is a very common metal roofing material, this article gives you complete knowledge. What is PPGI Coil? PPGI coil stands for “prepainted galvanized

Testimonials

What they say about us

Our Partners :