PPGI coil is a very common metal roofing material, this article gives you complete knowledge.

What is PPGI Coil?

PPGI coil stands for “prepainted galvanized steel coil.” It is a type of metal coil that is coated with a layer of paint and primer on both sides, which provides a protective barrier against corrosion and other forms of damage.

The PPGI coil is a popular material for roofing and cladding applications. Automotive and appliance industries use PPGI coils for manufacturing various components.

PPGI coils are typically made from hot-dip galvanized steel, which is then coated with a layer of paint and cured at high temperatures to create a durable, long-lasting finish. Rolled metal strips pass a continuous process in the application of organic coating material per requirement by the EN-10169-1 standard.

Cleaning and chemical pre-treatment per side or both sides of the metal surface take place during this process. It involves single or multiple applications of coating powder or paint. Lamination and curing with plastic films follow to ensure the durability of the coating.

Profile Structure of PPGI Coils

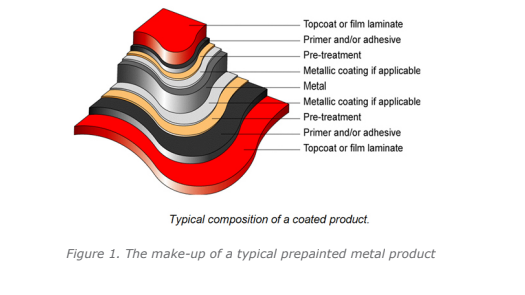

PPGI coil provides long-lasting and durable performance over the years. The method gives uniform cleaning, coating, and pre-treatment on the metal surface. The highly controlled coating process gives the metal coil several synergistic layers that include the following:

- Topcoat or film laminate

- Adhesive or primer, or both

- Pre-treatment

- Metallic Coating (if applicable)

- Metal

- Metal coating (if applicable)

- Pre-treatment

- Adhesive or primer, or both

- Film laminate or topcoat

Top coatings could be liquid paint, film, or powder paint. Prepainted metals have over 90 percent liquid paint.

Manufacturers may customize the coating layers depending on the application and customer specifications. It’s the coil coater’s job to choose the pre-treatment and primer for the substrate and top coating combination.

The coating thickness includes a thin layer of primer , but most coatings are the top coat. In some applications, a thick primer could be a high-build polyurethane. It comprises 50 percent of the total coating thickness.

PPGI Coil Manufacturing Process

A coil coating line runs at a constant speed in a processing zone using strip accumulators at the end of each line. It uses entry decoilers, equipment for cleaning, a primer coat, chemical pretreatment, curing, a final coating, an exit accumulator, and exit recoilers.

The coating line’s purpose is to coat metal coils with a layer of paint or other finishing materials. This process is vital in construction, automotive, and appliance manufacturing, ensuring the durability, corrosion resistance, and aesthetic appeal of metal products.

The coil coating line’s processing typically involves several steps. First, the metal coils are cleaned and pre-treated to remove any surface contaminants and prepare the surface for coating.

Next, a layer of primer is applied to improve adhesion and corrosion resistance. The primer is then cured through a heating process to ensure proper bonding to the metal.

Once the primer is cured, the metal coils are coated with a topcoat of paint or other finishing materials, such as laminates or adhesives. A topcoat application follows. It includes roll coating, spray coating, or electrostatic coating, depending on the specific requirements of the product.

The metal coils are cured again through a heating process. This step ensures the paint or finishing materials adhere to the metal surface and provide the desired level of protection and durability.

The coil coating line’s processing offers numerous advantages over traditional painting methods. It allows for a consistent, high-quality finish that is uniform across the entire surface of the metal coil. It also provides excellent corrosion resistance and durability, which are essential for products that are exposed to harsh environmental conditions.

Which is better PPGI Coil or PPGL Coil?

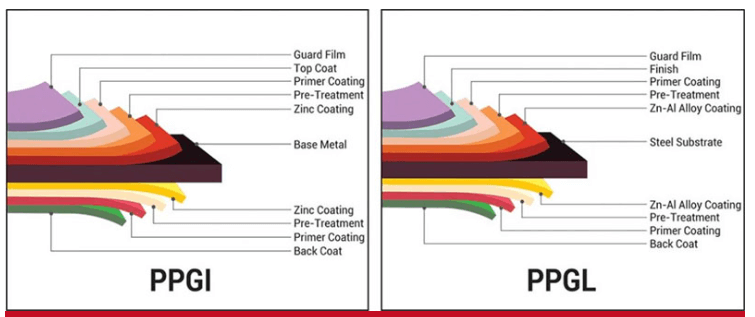

Whether PPGI or PPGL coils are better depends on the specific application and requirements. Know their differences:

PPGI coils have a zinc coating that provides excellent corrosion resistance and durability. It is typically used for indoor applications or outdoor applications where there is minimal exposure to harsh weather conditions.

PPGL coils have zinc and aluminum coatings that provide superior corrosion resistance and durability. It is suitable for outdoor applications where it will be exposed to harsh weather conditions. The aluminum also provides better heat resistance than zinc, making it a good choice for applications that require heat resistance.

PPGL weighs less than PPGI because aluminum is lighter than zinc. The aluminum-zinc coating with the same thickness of coating covers three percent more space compared to PPGI coil.

The service life of PPGI is shorter than PPGL, as it depends entirely on its zinc coating. The aluminum-zinc alloy of the PPGL alloy offers corrosion resistance. It can last up to three times longer compared to PPGI.

In terms of aesthetic value, PPGL has a smoother surface than PPGI. The aluminum in PPGL offers high-performing adhesive properties compared to PPGL. Galvanized sheets require more pretreatment for painting.

PPGL is more costly than PPGI due to its high performance. There are fewer licensees and manufacturers of PPGL. The cost of a PPGL sheet is 3 to 11 percent higher than that of a PPGI coil.

Purchase Guide

Choosing the right PPGI Coil material is related to the purpose and environment. PPGI Coil consists of galvanized steel coils and different paints. Here’s how to choose.

Choose galvanized steel sheet

Grade

Galvanized coil is the substrate of PPGI Coil, the first choice is to confirm the steel grade of galvanized coil, which is related to the use of PPGI Coil. Choose commercial steel and structural steel for construction. Commercial steel is a cold forming low-carbon steel for bending and prfiling quality. It is usually processed into corrugated roof tiles by cold forming machines. Structural steel is used for building facades and lightweight steel structures with a focus on yield strength.

Common commercial steel grades are DX51D to EN 10346 and CS type A to ASTM A653. Structural steel is S250GD, S280GD, S350GD, S550GD, etc. according to EN 10346 standard, and the number 550 means the yield strength is 550Mpa.

In addition to the application in the construction field, PPGI Coil can also be used as the shell of home appliances. For example, the shell of lamps needs DX52D material with drawing quality.

Zinc layer weight

The coating mass of galvanized sheet for construction is usually 30-275 g/m2. Z275 galvanized coil substrates are used in highly corrosive environments such as coastal areas, and Z100 galvanized coil substrates can be used in housing construction in ordinary environments.

Choose Paint

Polyester is PPGI Coil’s most widely used paint and it can provide an economical product. Has low resistance to the effects of UV rays and low corrosion resistance to chemicals. Suitable for areas with low environmental corrosion.

SMP has excellent scratch resistance and excellent adhesion, and is easier to chalk and fade under ultraviolet light than PVDF.

The main properties of High durability polyester(HDP) are strong weather resistance and strong corrosion resistance. It is mainly used in areas with long sunshine time, high dryness, large temperature difference between day and night, and strong humidity.

PVDF is relatively strong in anti-ultraviolet rays, not easy to decompose in sunlight, improves anti-fading and chalking ability, and maintains color luster for a long time. PVDF has strong corrosion resistance and is suitable for use in coastal areas.

Durability: PVDF >High durability polyester(HDP)>Silicon modified polyester(SMP)>Polyester(PE)

Select Coating Structure

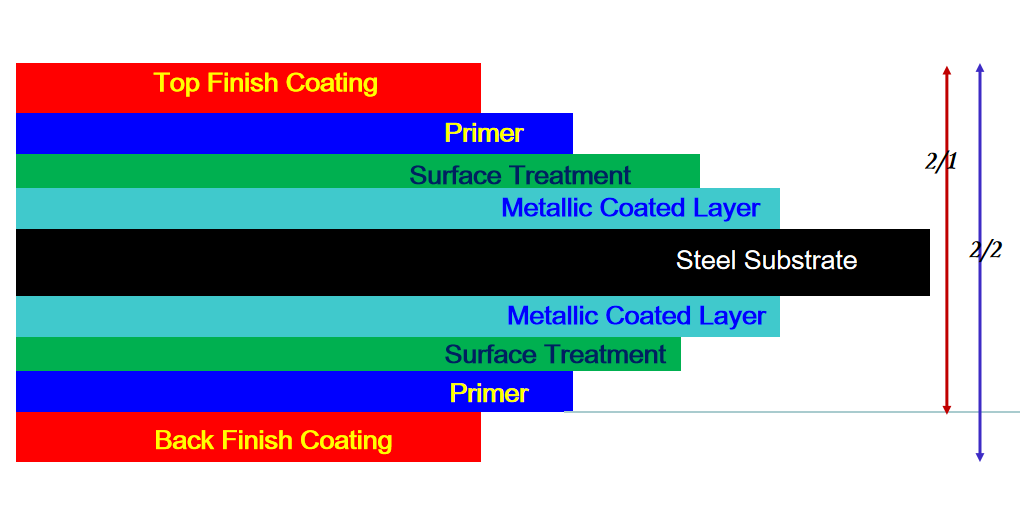

PPGI Coil has 2 coating structures, 2/1 and 2/2. 2/2 means top finish coating and back finish coating, and 2/1 means no back finish coating.

Sandwich panels are suitable for 2/1 structures, and high-durability roofs are suitable for 2/2 structures.

Conclusion

PPGL coils offer a long service life. However, if your application is indoors or will not be exposed to harsh weather conditions, a PPGI coil may be more cost-effective.