Prepainted steel coil undergoes several stages to ensure its high performance for various applications. Find out why prepainted steel is more cost-effective and superior than standard steel products.

What is Pre-Painted Steel Coil?

Pre-painted steel coil, also known as pre-coated steel coil or color-coated steel coil, is a product made of hot-dip galvanized steel sheet, hot-dip galvalume steel sheet, electro-galvanized steel sheet, etc. that has been coated with one or more layers of organic paint or other protective coatings.

The pre-painting process protects the metal substrate from corrosion. It improves its durability and aesthetic appearance and provides a wide range of color choices.

According to the EN-10169-1 standard, an organic coating material is applied to the rolled metal strip to protect it from corrosion. Cleaning and pre-treatment of chemicals are applied to one or both sides of the metal surface with a single or multiple coats of paint or powder.

Pre-painted steel coils are widely used in various applications, such as:

- indoor and outdoor applications in building and construction (roofing, wall cladding, garage doors)

- domestic appliances (refrigerators, washing machines, bakeware)

- cabinets and office furniture

- transport and automotive sectors

- lighting fittings

Pre-painted steel coils come in a variety of color coatings, surface textures, and gloss levels. The paint coatings have high chemical resistance, flexibility, and non-stick properties.

The coated coils are available in different cuts. Customers may request coils with narrow widths, profiled, deep drawn, and different lengths and shapes. There are a variety of pre-painted steel coils as manufacturers continue to develop modern designs and coatings.

Substrate of Pre-Painted Steel Coil

The substrate of a pre-painted steel coil refers to the base metal, where the organic coating takes place. The substrate of pre-painted steel coil include the following:

Hot Dipping Galvanized Steel Coil

Hot-dip galvanized steel coil is a substrate made by immersing steel in a bath of molten zinc to create a layer of zinc coating that protects the steel from corrosion. This method adopts galvanizing production as a continuous process. The cold-rolled coils stay in the dissolved zinc bath to continue their galvanizing process.

Hot Dipping Galvalume Steel Coil (55% aluminum/zinc)

Hot-dip galvalume steel is a popular choice for cladding and construction uses. This substrate offers corrosion resistance to the steel when exposed to harsh environments. The zinc coating provides galvanic protection when the steel surface suffers from scratches over many years of use, keeping the steel functional and intact.

Zinc-magnesium-coated steel

Zinc-magnesium-coated steel replaces steel and has a coating of 1 to 3.5 percent magnesium and 0.5 to 3.5 percent aluminum. It achieves metastable eutectic structure by fast cooling after a molten zinc bath.

The steel has a better performance against corrosion compared to hot-dipped galvanized steel, which has a pure zinc coating. Zinc, magnesium, and aluminum form an oxide protection layer on the steel, which means it can stand against corrosion at the exposed edges and boundary layer.

Product Life of Pre-Painted Steel Coil

Pre-painted steel coils can last for several years because the paint offers an extra layer of protection to the steel. Paints contain corrosion-inhibiting agents that can thwart moisture, heat, oxygen, and corrosion-inducing agents from causing damage to the steel.

Although paints fade over time and become dull due to heat, they can minimize the damage to the steel even if moisture penetrates the paint. Paint manufacturers have developed paint coatings with advanced features by adding corrosion-inhibiting agents.

These inhibiting agents lie at the interface between the metal and the paint coating. They minimize rusting and corrosion to the steel. The inhibiting agents protect the metal from losing its adhesion to the paint when there are blisters and scratches at the exposed areas.

The agents also protect the paint from undercutting corrosion, so the metal does corrode even if there are scratches and cut edges. Paints help improve the product life of steel sheets and coils depending on several factors.

These factors include the paint coating thickness, resistance to harsh environmental conditions, primer coating, and paint pre-treatment that contains corrosion-inhibiting agents.

Choose a paint that has a lower moisture permeability. This type of paint protects the steel from flaking and blistering due to water absorption. Optimizing the product life of pre-painted steel coils depends on the choice of paint and treatment technology.

Choose a paint that contains corrosion-inhibiting agents. Ensure that you apply the right primer coating, metallic coating type, and pre-treatment to make the steel last for years.

Source:

https://www.galvinfo.com/wp-content/uploads/sites/8/2017/05/GalvInfoNote-4-1.pdf

Paint System Durability

Although pre-painted steel coil greatly extends the service life of the product, when the life reaches the limit. They may fail in some aspects, like fading and chalking, that affect the aesthetic value of the product.

Paints are prone to blistering and flaking over time. It occurs when the paint separates along the pretreatment or metallic coating bond line, the primer or pre-treatment bond line, and the primer/paint bond line.

There are factors that influence the durability of the paint system. Such factors are in relation to the combination of the pre-treatment, primer, and paint coating to the elements and environmental conditions. Paints may lose their adhesion if there is corrosion of the steel substrate.

Latitudinally undercutting corrosion is the most common form of paint failure. It is due to a scratch at the exposed edge or in the paint. Chemical reactions, moisture, and heat exposure can also cause bulk corrosion and degradation of the adhesion bond, which leads to paint damage.

Advantages of Pre-Painted Steel Coil

Prepainted steel coils have an organic coating layer that offers resistance to corrosion and guarantees longevity. Here are the advantages of pre-painted steel:

Advantages in Design

Prepainted steel products are aesthetically appealing due to their design, texture, and color variations. The surface finish comes in printed films that look like woodgrain, matte, high gloss, embossed, orange-peel, or smooth. They are available in various aluminum alloys and grades that are easy to bend and adjust during application.

Manufacturers are producing sustainable and recyclable prepainted steel. This steel has a superior performance against corrosion despite its thinner organic coatings, which are common in post-applied films and powder. The organic coatings are less costly as they do not need regular repainting and maintenance.

Sustainable in Life Span

Prepainted metals undergo a coil coating process that offers long-lasting service without costing much. Since they are organic paint coatings, they are less costly but offer a sustainable, effective, and reliable design solution for various applications.

Manufacturers take close supervision during the coating operations, ensuring that the prepainted metals yield a premium, recyclable, and sustainable design that can last for up to forty years in the harshest environments.

Coil Coated Metal Joining and Forming

Prepainted metals have a high formability, which means they are easy to bend, blank, form, draw, and rewind. Driving mechanical fasteners like rivets, screws, bolts, and Tog-L locks does not require extra force. They are easy to bind using an adhesive bond or lock seam.

They are weldable and formable into different shapes due to their aluminum content. The surface is free of dirt and imperfections as the aluminum and steel undergo cleaning, priming, painting, and curing. They offer superior performance to their post-painted counterparts.

Prepainted Metal and Cut-Edge

Prepainted steel coils boast of their prepainted cut-edge that offers superior performance for several years. The reason is that cut edges are less susceptible to corrosion compared to post-painted metals without exposed edges.

Source:

https://prepaintedmetal.eu/874/889

https://prepaintedmetal.eu/875/benefits

Types of Top Coating

Pre-painted steel coils offer a long-lasting solution to building and construction needs. They boast of an organic coating layer that guarantees high resistance to corrosion, making them last for years compared to galvanized steel sheets. Their base metals consist of HDG electrogalvanized, hot-dip zinc-aluminum-magnesium, and cold-rolled.

Here are the top coatings on prepainted steel sheets and coils:

Polyester (PE)

Polyester coatings offer solidarity and flexibility to the metal sheets due to the monomer reactants used during the formulation of the polyester resin. These reactants have the ability to regulate the polyester’s performance during application. They consist of physical properties that enable them to resist weathering and degradation to the metal over many years of use.

High Durable Polyester (HDP)

High-durability polyester resin refers to a coating consisting of a high-molecular-weight polyester resin with a lesser amount of branched polymer. The polyester resin can be hydroxyl or carboxyl functional, which offers superior resistance to ultra violet compared to an ordinary polyester resin. These high-molecular-weight resins contain a high amount of isophthalic acid and can withstand aggressive environments.

Silicone Modified Polyester (SMP)

SMP is an improved version of commercial coil coatings due to its solvent-based chemistry. Comparing with PVDF coatings, SMP’s polyester can stand against weathering, while its silicon content offers gloss coating retention. The downside of SMP is that it is less flexible because the polymers have a branched structure and high crosslinks.

Polyvinylidene Fluoride (PVDF)

PVDF is a solvent-based architectural paint system that has superior weathering properties compared to other coating types. Its vinylidene fluoride monomer undergoes homopolymerization. This method allows the production of materials with an unobtrusive molecular weight and size suitable for a specific application.

The melamine-acrylic composition of PVDF is 70 percent PVDF and 30 percent acrylic for superior weathering performance and properties. Its downside is that it is costly and less flexible.

Source: https://www.galvinfo.com/wp-content/uploads/sites/8/2017/05/GalvInfoNote-4-1.pdf

Process of Pre-Painted Steel Coil

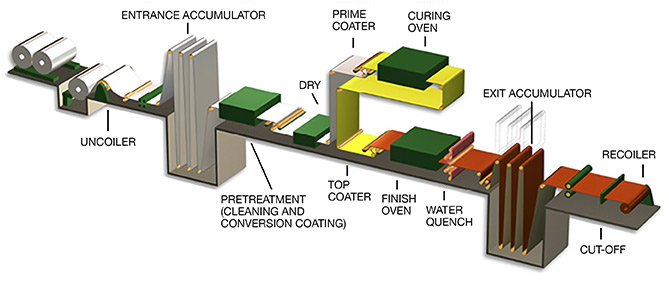

The fabrication of prepainted steel coils and sheets begins with the delivery of the substrate in coil form directly from the rolling mills. There are three sections involved in the coil coating line: entry, processing, and exit.

Each step ensures that the finished prepainted metal products are durable, high-performing, and aesthetically appealing. The machines in the production line work simultaneously to paint 2,000 to 4,000 square feet of metal strips per 4 minutes.

Here are steps at the coating line:

Step 1: Cleaning the Metal Strip

Cleaning up the oil, dirt, and impurities of the cold-rolled coil involves brushing, an alkaline dip, a water bath, or brushing.

Step 2: Application of Zinc and Alloy

The application of aluminum and zinc depends on the application and customer requirements. Some products consist of 100 percent zinc, while others contain magnesium alloy.

Step 3: Treatment of the Surface

This step is vital to ensuring that the paint and primer bond well with the metal strip. Due to some chemical restrictions, the surface is treated with chemicals, such as alkaline oxidation, depending on the supplier and country of origin.

Step 4: Metal Rinsing and Drying

Rinsing the metal strip helps ensure that it has no chemical residue before applying primer. Drying the metal is a must to ensure that the subsequent layers bond well.

Step 5: Application of Primer

A coating of primer can be on one or both sides of the metal strip. Primer application hastens the adhesion of the finished paint layer.

Step 6: Curing and Cooling the Strip

Curing takes 15 to 16 seconds. This method allows the primer to harden, dry, and reach the desired temperature before applying the next coating.

Step 7: Front and Back Coating

This step is the final painting stage, wherein two-coat paint systems are applied.

Step 8: Drying, Curing, and Cooling

The product undergoes this step to ensure that the steel product is ready for rewinding, rerolling, and shipping to end users.

Step 9: Packaging

Image showing a coil coating line schematic.

Source: https://www.coilcoating.org/process

Conclusion

The choice of steel substrate depends on the specific requirements of the application. Users must consider the level of corrosion resistance, aesthetics, and cost when choosing a steel product.