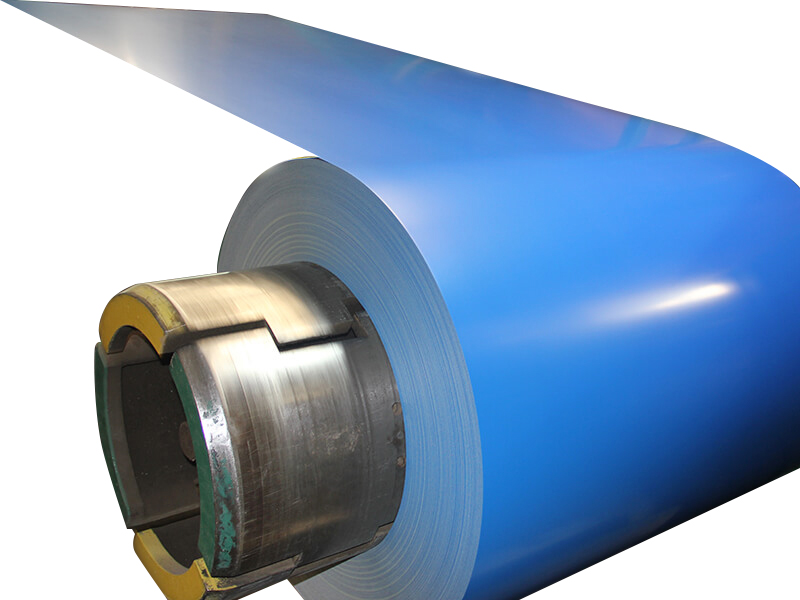

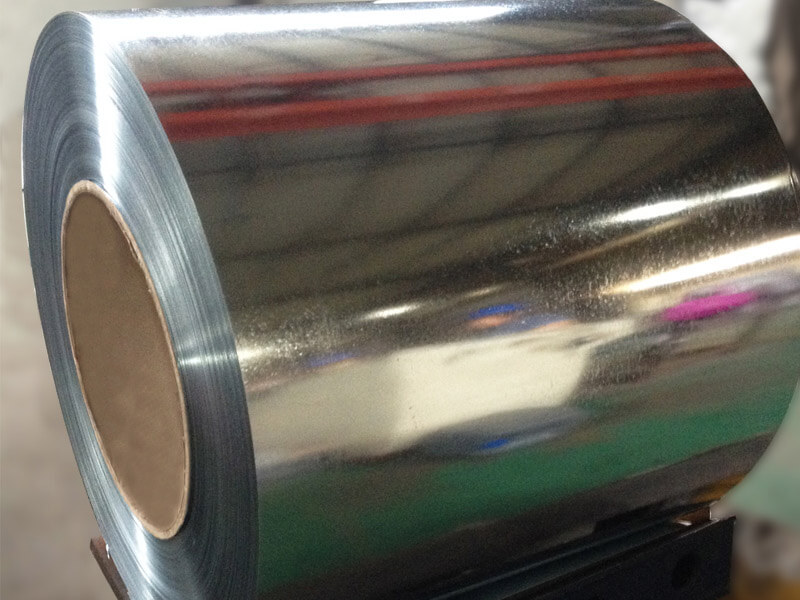

A 24-gauge metal coil refers to a sheet metal or metal panel that has a thickness corresponding to the 24-gauge standard. An aluminum with this gauge has a measurement of 0.511 mm, or 0.0201 inches. Steel measures 0.0239 inches, or 0.607 mm, while galvanized steel measures 0.0278 inches, or 0.627mm. It has an average measurement of.023 inches, according to industry standards.

Manufacturing and industrial sectors choose 24 gauge because it is resistant to harsh weather conditions and its appearance lasts longer. Since it has a lower value than 26 or 29, it is costly, making it less appealing to homeowners.

Is 24 gauge metal strong?

A 24-gauge metal sheet or panel is more durable against harsh weather conditions than 26- or 29-gauge metal. It can stay longer without resulting in oil canning, unlike 26 gauge. It does not show a bubbling effect as it does not require a tighter fastener. It is a thicker metal compared to metals with higher gauge numbers.

Its durability guarantees that the roofing applications offer a balance between weight and strength. It is the best choice in the manufacturing and construction industries. It is suitable for siding, metal panels, roofing, and other structural components. Compared to 26-gauge metal roofing, it offers increased strength and durability to the structure.

It provides excellent structural support and resistance against damage and dents, even in areas with extreme weather conditions. Comparing 24-gauge metal, it is still considered lighter than 22 or lower gauges. Its strength and weight are manageable for various applications without adding excessive weight.

Its thickness and durability make it suitable for areas frequented with hail, heavy snow, hurricanes, strong winds, and typhoons. Its ability to withstand dents and oil canning makes it a good choice for homes and villas.

Although it might be an expensive metal gauge, it is the best option for countries with harsher climates. Its strength can handle heavier snow and higher winds than 26-gauge metal roofing. It is an expensive option, yet it offers a long-lasting result that could still be considered economical and practical. The increased thickness of 24-gauge has a lesser chance of getting punctures and dents from snow than using 26-gauge metal roofing.