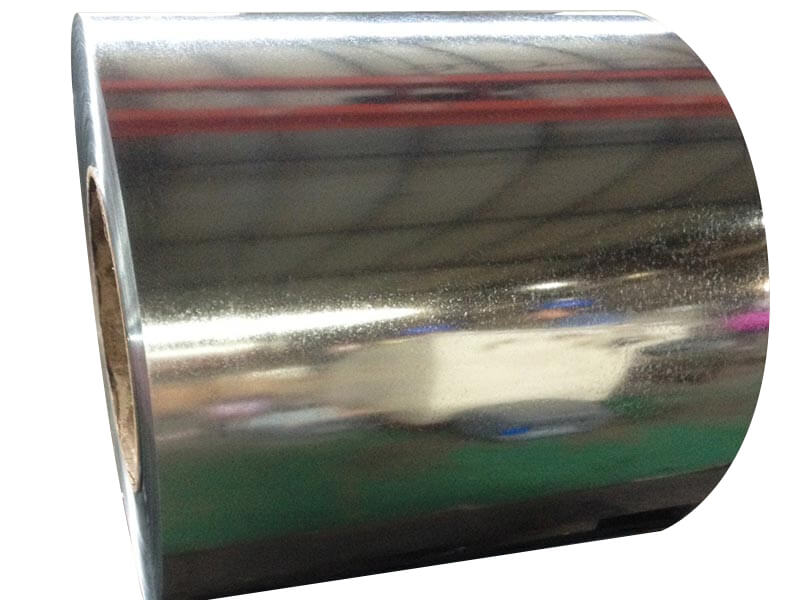

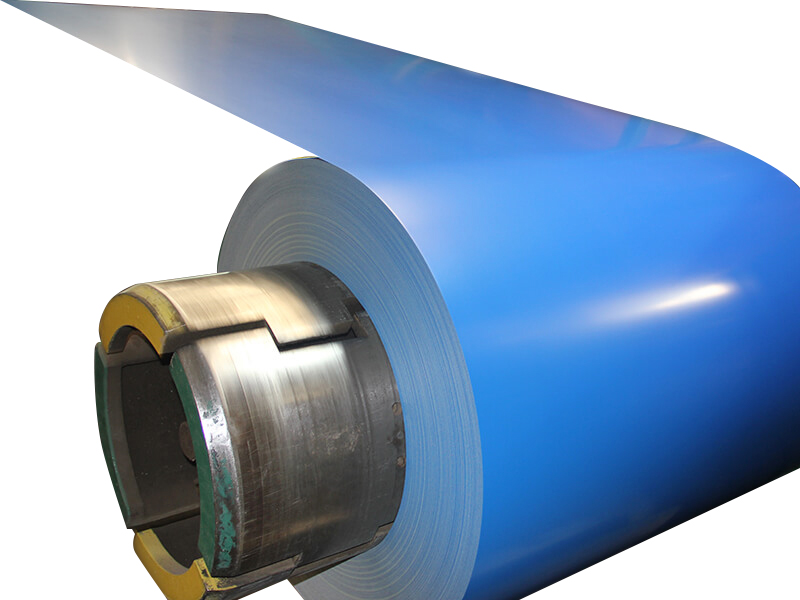

What is Galvanized iron sheet?

Galvanized iron sheet is a material consisting of a zinc layer applied to sheets of metal that go through a process called “Hot-Dipping”, in which the metal sheets go through a molten zinc bath. The zinc then bonds to the iron particles within the steel sheet and forms a protective layer on both sides.

Hot-Dipping is a process that helps protect metal materials such as steel sheets from corrosion caused by potential exposure to extreme environments. This is achieved through multiple processing types and it protects materials over a long time from degrading whilst maintaining their original properties unaltered.

While going through the molten zinc bath process it causes a reaction that bonds both metals’ external layers, thus creating a similar but highly resistant surface. The metal sheet then can be produced to a finished state because the zinc coating doesn’t flake or peel off during the manufacturing.

The finished metal then goes through a spinning process and can withstand corrosion with none added or secondary paint coating which makes it the most economical process for protecting steel.

Only using a magnet or a gauge can determine if the produced metal has a zinc coating, as a matter of fact sometimes then you see a gray coating it could mean the part has been painted, as a layer of paint would add thickness to it and the only real possible way to determine if it’s been “Hot-Dipped” can be achieved by running a laboratory test.

Chosen for over a century for being the most effective way of protecting metal from degrading, the “hot-dip” process is mostly chosen for its versatility and sustainability. It guarantees the materials’ durability over time and has a significant lower investment cost comparing to other materials.

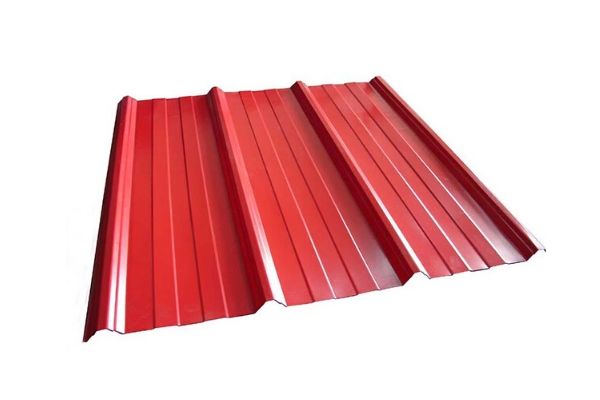

How much is a galvanized metal roof?

Galvanized metal roofing prices vary on quality and the market. The cheapest average retail price in the US costs around 5.63$ and it can go up to 6.95$ per square foot (0.09m²).

Will galvanized steel roofing rust?

Galvanized steel will keep its strength for a significant time before it starts to deteriorate. Although regular steel is formed of iron which can rust when exposed to moisture either within rain or humidity. And over time rust will corrode a steel part to the point of failure.

How do you install galvanized roofing?

You might need to cut the panel to a desired length as for most panels come up to 30 feet (9.1 m) in length. And it would be best if you allow for a minimum of 20 inches (50 cm) if you need to lap to complete the cutting.

Some panels have pre drilled holes. If yours do not, then you will need to drill holes in them.

Install the panels. Place them directly onto purlins that are attached to the roof trusses, beginning on the outside edge.

Screw down the panels. Drill the holes, and use screws with polycarbonate washers.

Complete the opposite side. If your roof is 2-sided and not just a single slope, you can repeat the installation on the other side of the roof, and install a ridge cap as you proceed across with the panels.

How do you cut corrugated galvanized steel?

Determine where the part needs to be cut while having it placed on a flat surface and after measuring it.

Then draw a line down the length or width of the sheet metal using a pencil or marker to mark a cut line. You can cut sheet metal both parallel to the edges, as well as across them.

Hold a magnet up to the sheet to work out if it’s steel or another material. If the magnet is attracted to the sheet metal, then it is made of steel. If not, then it is made of another metal.

Start cutting with a pair of straight edge snips at the top of the marked line, if the sheet is steel. Use a pair of tin snips at the line if it’s tin, aluminum or etc. Both of those tools are basically industrial strength scissors.

Cut along the pencil line with the straight edge shears or the tin snips until you’ve got cut the enter piece of corrugated sheet.

How long does a galvanized roof last?

Although humidity helps corrosion, temperature itself has less of an impression.

Galvanized coating does well in extreme environments due to its protective layer.

The zinc layer of “hot-dipped” galvanized metal will last within the worst soil from 35 to 50 years and in less corrosive soil for 75 years or more.

How do you age corrugated galvanized steel?

First step go aging galvanized steel is to wear protection because you will be using chemicals that can irritate the skin.

Secondly you need take some steel wool and sand the piece you want to age as you’ll want to scrub off the protective coating as much as possible for it protects the piece from the elements. This is what the wool is good for.

Thirdly you are going to squirt some toilet cleaner which can be found in every household or a grocery store all over the piece. It is said the more you apply, the better it works. Take your wool again and use it to help scrub the toilet cleaner along the piece you want aged. It will naturally settle into all of the crevices, but also make sure to scrub it into all of the ridges as well for maximum coverage.

Fourth you will have to wait for the cleaner to do its work for around 24 hours. If you have a warm and sunny day, you won’t need to wait as long. When it seems ready clean up the metal with a wet towel to wipe away the cleaner.

Finally you should be left with a beautifully aged piece. If the metal isn’t aged as much as you would prefer, just repeat the process.