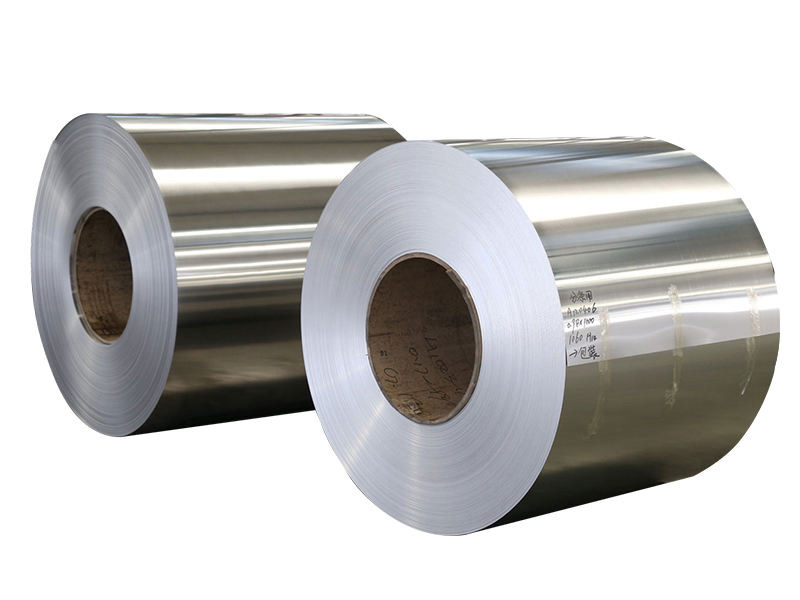

1100 Aluminum Coil is a widely-used industrial soft, low-strength metal for making chemical equipment, heat exchangers, and decorative trim applications. This commercially pure alloy has 99% or more aluminum content compared to other alloys. The remaining elements that it contains are iron, copper, silicon, titanium, magnesium, manganese, zinc, and vanadium in very small amounts. It is created through a cold working process which means that it is formed or shaped near or at room temperature. This type of aluminum alloy is not a suitable material for high-pressure, high-strength, or hardness applications.

Properties of 1100 Aluminum Coil

- High corrosion resistance – Its excellent resistance against rust and corrosion makes it an ideal material for making storage equipment.

- Thermal and electrical conductivity – It is good for chemical and food handling that requires solid yet safe handling. It has 25 °C thermal conductivity and 25 °C electric resistivity.

- Low density – It is lightweight and easy to shape or move to different locations. Aluminum, generally, is only 1/3 of the density of copper or steel.

- Good plasticity and high weldability – Being one of the softest aluminum alloys, it can be shaped easily by spinning, stamping, or drawing processes that do not require high heat. It is best used for soldering, brazing, and welding.

1100 Aluminum Coil Uses

Making products

Its malleability makes it valuable to various industries in producing commercial and household products. This includes cooking utensils, chemical equipment, fin stock, rivets, reflectors, railroad tank cars, dials, bottle caps, nameplates, printed board, and a lot more.

Plumbing, lighting, and industrial materials

1100 Aluminum Coil is used to make heat sinks, building materials, heat exchanger components, cookers, hollow hardware, reflectors, and welding combination keys. It can also be formed into sheets, strips, wires, rings, plates, foil, rods, or round bars.

Natural finishing

It is nonmagnetic with great finishing capacity, making it a perfect choice for various decorative purposes.