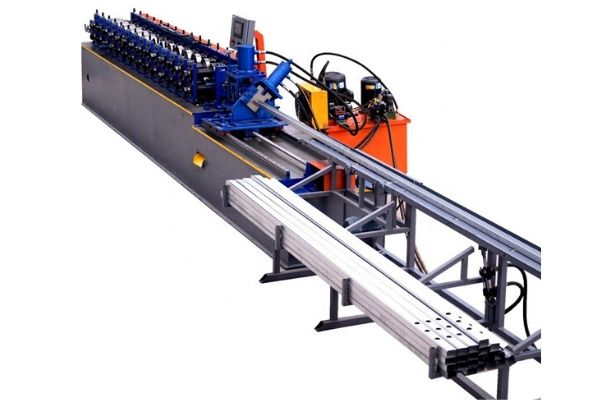

The Introduction of the Gutter Roll Forming Machine:

The gutter roll forming machine equipment is mainly composed of an active belt shaft, a leveling device, a side wheel for squeezing thick sides, a forming host, a forming cutting device, a hydraulic station, and a computer control cabinet.

The equipment adopts automatic control software to realize the informational management of the production.

The sink equipment also has the advantages of simple operation, easy maintenance, being easy for mechanical debugging and easy mold replacement.

The automatic control system of the entire equipment applies a highly integrated network to make the automatic system more superior.

The Process Flow of the Gutter Roll Forming Machine:

Uncoiler—–Feeding Guide Part—Forming Part—-Hydraulic Station Punching—-Discharge Rack

The Features of Gutter Roll Forming Machine:

- The whole gutter roll forming machine adopts PLC automatic control system, and diverse safety protections can be set, which have effectively avoided the appearance of accidents.

- The bed of the machine is made of welded steel plates which will be tempered for effectively eliminating the internal stress of the machine, so that the body of the machine will be not easy to deform.

- The forming frame of the machine is welded by channel steel.

- The roll shaft of the machine is made of 45# steel, which has been quenched and tempered.

- The material of the forming punching mould of the machine is Gr12.

- All rollers of the machine are polished on the surface of CNC lathe to ensure accuracy.

- The machine has a long service life, which can up to 10 years.

The Classification of the Gutter Roll Forming Machine:

It can be divided into K type gutter roll forming machine, semicircular gutter roll forming machine, and standard box gutter roll forming machine.

The Advantages of the Gutter Roll Forming Machine:

- The electro-mechanical anti-seismic support system is firmly connected to the pipeline, trough system and equipment of the built anti-seismic planning structure. It is mainly used for bending objects, which will reduce the labor costs and greatly improve the work efficiency under the traditional mode.

- The anti-seismic bearing does not need welding and drilling, which can be assembled through components. It can be easily disassembled, modified and adjusted, and can be reused for several times.

- The machine has good toughness, good low temperature impact resistance. It can resist the power of shocks. And it is not easy to dent, resist bending or deformation.

- The PVC material of the machine has the special characteristics of anti-ultraviolet, which can resist long-term sunlight exposure, and also increases the resistance to acid rain and air pollution.

- The machine has good aging resistance, acid, alkali and mildew resistance, as long as new, with no need for renovation and painting.

- The machine is easy to cut, install, with no need for any special tools.

- Mature formula technology ensures the superior stability of the performance of the product.

The inspection and cleaning of the gutter roll forming machine mainly includes three parts: hydraulic oil circuit, hydraulic components and filters:

- Hydraulic circuit:

The gutter roll forming machine should also be checked after the hydraulic system has been repaired, and the oil level of the fuel tank of the machine should be checked once a week.

If the oil level is lower than the oil window, then hydraulic oil should be added.

The system oil temperature should be maintained between 35°C and 60°C, and should not exceed 70°C.

The oil should be replaced after every 4000-6000 hours of work, and the oil should be replaced after 2000 hours of work on a new machine.

Every time the oil is replaced, the oil tank should also be cleaned.

- Hydraulic components:

Note that cleaning agents cannot be used.

The hydraulic components (base plate, valve, motor, pump, oil pipe, etc.) should be cleaned once a month to prevent the dirt from entering the system.

Check whether there is any deformation in the bends of the oil pipes of the gutter roll forming machine.

After using the new gutter roll forming machine for one month, it should be replaced if it is abnormal.

After two months of use, the connections of all accessories should be tightened, and the system should be shut down during this work, and the system has no pressure.

- Filter:

The filter should be replaced or cleaned in time.

Every time the oil is changed, check and clean should be carried every 3 months.

The air filter on the fuel tank should be replaced once a year.

FAQ:

The Introduction of Gutter:

The Gutter mean to the hollow section between the two crotches of the roof of a building.

The drainage of the roof can be divided into organized drainage and unorganized drainage (free drainage).

The organized drainage in general gathers the rainwater into a gutter and then drains it from a round pipe.

The part that gathers rainwater is called a gutter. The gutter can be divided into inner gutter and outer gutter.

The inner gutter refers to the gutter inside the outer wall, usually with a parapet.

The outer gutter is the gutter that is picked out of the outer wall, and generally does not have a parapet.

The advantages of the structural design of the gutter:

- The gutter and cover are exquisitely produced, and the components are connected by inserting part to ensure that the system does not leak and drains more smoothly.

- The decorative cornice design can integrate with the architectural style of the house, which seems like the original parts of the building.

- The carefully designed double-wall structure maintains the endurance and rigidity of the natural mix system.

- The inner wall of the gutter is designed with a small arc edge, which is mean to prevent the dirt from accumulation and is easy to clean.

- The matching fixed components enable the gutter to adapt to any angle of installation surface.

- The design of the fixed clip makes the downpipe look beautiful and elegant in appearance, and can be firmly fixed to any external wall façade